Dive Brief:

- Airbus has experienced delivery slowdowns for customers due to faulty engine production , The Wall Street Journal reported.

- Engine maker Pratt & Whitney has replaced numerous geared turbofans on multiple A320neo planes already delivered by Airbus. The French plane maker also sources engines from GE and Safran SA, which will provide about half of the engines needed for the company to meet its targeted delivery of 720 new planes.

- Airbus is also struggling with French cabin interiors specialist Zodiac Aerospace SA, which has fallen behind on building seats and toilets for the Airbus A350 long-range jet. Only 13 A350s made it to customers in the first three months, despite a projected plan for roughly 80 deliveries before the end of the year.

Dive Insight:

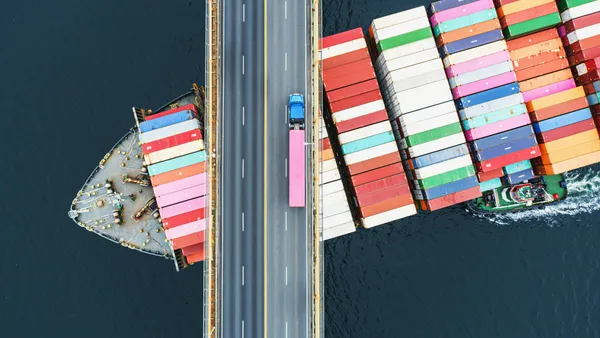

Although Airbus still intends to meet its projected 2017 delivery targets, delays by suppliers can have a massive impact on manufacturers, tangling the supply chain and causing disruption throughout the industry.

In fact, a recent survey of buyers, engineers and procurement professionals conducted by Thomas.net reported that delivery performance is the most important part of a company's shortlist when evaluating new suppliers. Warning signs that a potential supplier cannot be relied upon can be easily ascertained.

Here are a few issues to consider carefully when assessing a new supplier:

Delays can occur within any system. Yet, recurring delays due to circumstances that can't be verified are often a sign of disorganization, no matter how many apologies or promises of future perfection are offered. However, when something does goes wrong, does the supplier understand and take ownership of the delays?

When an inspection is due, is the supplier ready and willing to open doors? Transparency is a buzzword that impacts all levels of the supply chain, but is especially critical for maintaining necessary operational standards.

Finally, does the supplier himself have easy access to needed materials? If not, it could be a sign that the supplier's own operations are struggling and their inventory issues can trickle down to the manufacturer.