Big Data is a buzz phrase these days, for good reason. Using large data sets for analysis and planning purposes, those in the supply chain can react faster to changes at different points along the chain.

“It’s about re-imagining what we believe to be tried and tested supply chain processes, in light of the technology advancements and additional information available to us,” says Puneet Saxena, Vice President of Industry Strategies at JDA.

Data, he says, can be used to improve the customer experience and create a competitive advantage. So while there are many ways to apply it, here are four trends in how supply chains are using Big Data today.

Real-time tracking

The internet of things (IoT) allows companies to track what’s leaving their shelves in real time, whether at a warehouse or retail store.

Add in Big Data coming from social sources (e.g. Facebook, Twitter), news, events and weather, companies can better predict and plan future inventory instead of relying on historical data, says Saxena. For example, a store running a weekend promotion can track sales on a real-time basis, versus once daily. Taking into account current sales, along with social media responses to the promotion and potential weather events, the company can quickly adjust their supplies and warehouse shipping plans.

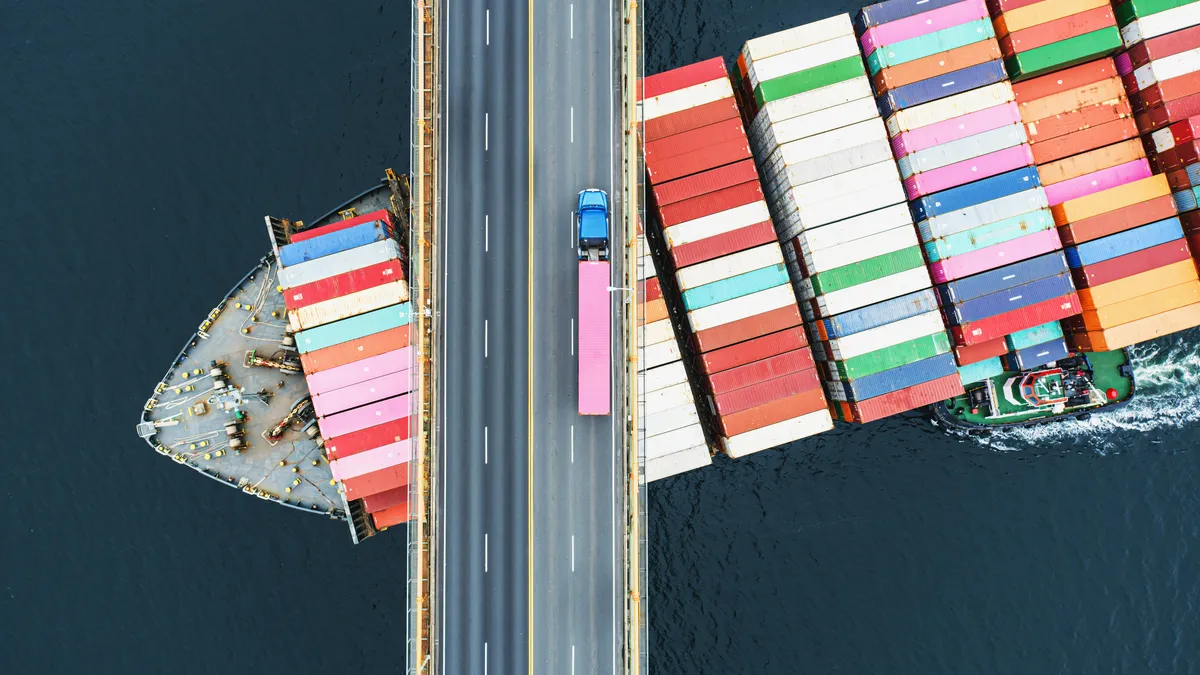

Up until a few years ago, retailers tracked this from ERP systems, incorporating orders, inventory levels and staffing data, said Saxena. That information was updated daily to every few weeks. But now IoT sensors, satellites, radar, smart phones and social media provide Big Data to get current location of aircraft, ocean vessels, trucks and parcel shipments. Saxena adds that with this information, software systems know which trucks are heading toward an ice storm region, and by incorporating weather prediction data, companies can adjust forecasts and shipment new arrival times. If a truck will be late, the company can get resupplied from an alternative warehouse or expedite a shipment.

"It’s about re-imagining what we believe to be tried and tested supply chain processes."

Puneet Saxena

Vice President, Industry Strategies, JDA

With better technology, companies like OU Kosher no longer need to track shipments using faxes and phone calls. The company, which certifies ingredients and finished products as kosher, tracks ingredients like oil from the processing factory to the packaging or its final product.

That might mean following a batch of soy bean oil created at an Iowa factory, transported via rail car to a holding tank at the New Orleans port, transferred it to an ocean vessel’s shipping container, drained into a South American port’s holding container, then moved to a truck going to a factory that uses that oil in its products. Every time the oil moves, OU Kosher needs to know, adding a new data set, says Rabbi Simcha Smolensky, Senior Field Representative for OU Kosher. “It has to be done in real time to keep production going,” he says. “Before it was a lot of phone calls, faxes and physical documents that you hoped made the transit.”

Supplier sourcing

Maintaining large data sets allows companies to more easily track their suppliers and make changes quickly.

OU Kosher monitors 8,500 facilities making 800,000 kosher-certified products, says Smolensky. To do this, they monitor 1.75 million ingredients. When a Chinese factory under their supervision lost their kosher certification, OU Kosher had to alert companies who used those affected ingredients, as continued use would render all products using them unkosher.

“Our system allows us to instantly track all facilities using the problematic material and we can get in touch with them in moments to alert them there’s a change,” Smolensky says. They could also tell the facilities the cut-off date for using the impacted ingredients, and offer available alternatives from their database.

It’s easy to see how other manufacturers would use databases like these in a similar way.

Customer segmentation

Using customer data, retailers can segment their buyers and markets to offer them the most customized products and services.

Saxeny says that software can help companies segment customers into individual personas, to tailor the supply chain by purchasing habits, like being early adopters or value shoppers, for example. Using Big Data, companies can also adjust the supply chain by market, providing each store with specific items of interest to their buyers. While this isn’t a new concept for retailers, with Big Data, there’s a wealth of information available, which can be parsed more specifically.

Smolensky says that one of his grocery store customers used Big Data to re-envision their stores, using data from the scanners’ UPC codes. Seeing the higher checkout value for kosher customers, the store realized there was a significant upside to catering more to that community. The store added additional kosher food aisles, as well as kosher butcher, deli, bakery, and restaurant departments. “The store bloomed into a major destination for kosher shoppers, all based on tracking of consumer data,” Smolensky says.

Using Big Data wisely

While Big Data is important, it shouldn’t be the overall decision maker, said Richard Weissman, Director of the Organizational Management Program and Center for Leadership at Endicott College Gloucester. "Supply chain is still a people business," he says. "Those people need data to do their jobs, but it doesn’t replace the person doing the jobs."

"Those analytics are great, tracking is good and the automating of processes through technology is wonderful," Weissman added. But there needs to be someone behind the data. Data won’t replace a relationship or a person walking around a factory floor.

"The data won’t call your supplier in the middle of the night. Data won’t be restocking the shelves, though it may give you insights on to that," he says. Big Data gets caught up in a lot of hype but it exists to drive value all along the supply change.