Dive Brief:

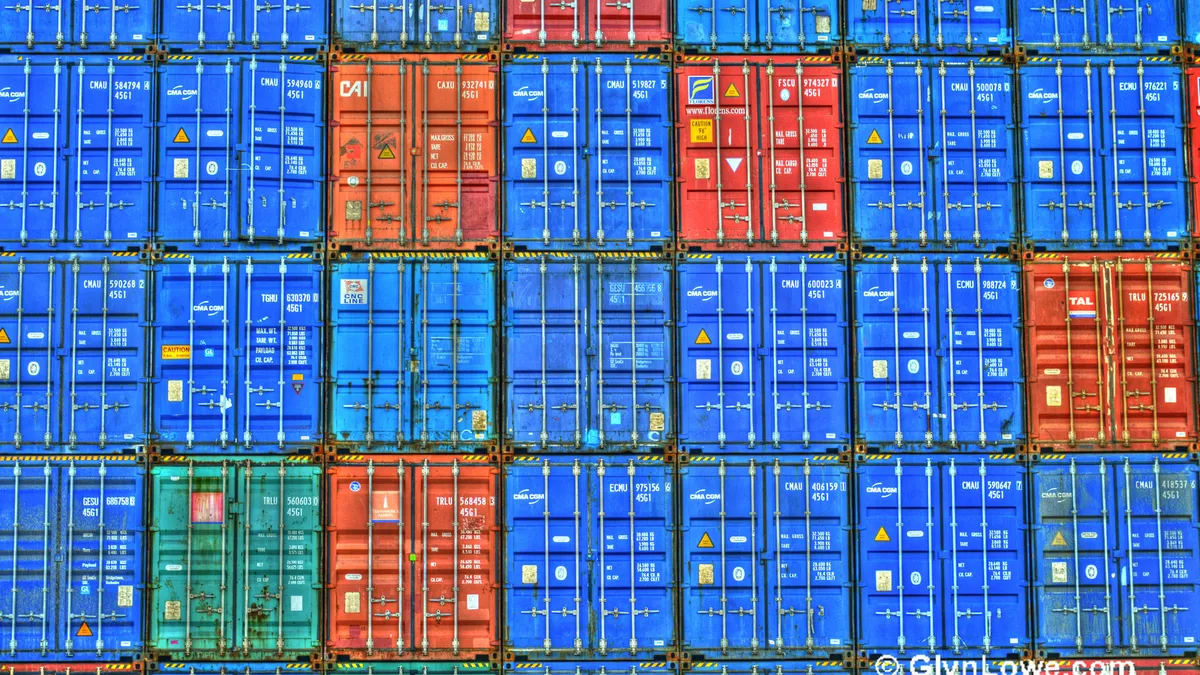

- Improving the speed of cargo passage through the Ports of Los Angeles and Long Beach to minimize container dwell time has become a prime concern, the Journal of Commerce reported Tuesday.

- Both ports, in creating a supply chain optimization task force, agree that the rapid transmission of information about cargo flow and space availability will better inform marine terminals, truckers, and beneficial cargo owners (BCOs), allowing for faster removal, loading, and drayage.

- While dwell time has already shrunk significantly thanks to the removal of port-clogging Hanjin containers, the establishment of ongoing solutions-based meetings will ensure dwell times continue to fall.

Dive Insight:

An established schedule for tracking dwell time is the simplest means of measuring improvement.

For example, containers which dwelled more than 5 days at both ports shrank from 8.6% in October to a mere 7.4% in November, 2016. This information becomes useful when shared with a supply chain manager looking to forecast lead times, specially as demand-driven and just-in-time manufacturing becomes the norm.

Some other ports are already reporting dwell times, but the practice is far from comparable. For example, an examination of dwell times at the Port of Virginia shows dwell times have on average fallen since November at Virginia International Gateway but risen at Norfolk International Terminal, both in Norfolk, VA. Consistently comparing these trends across ports, to include, say, Savannah, New York and Charleston as well would be rote and challenging, even for an annual task. It's possible, but inefficient.

For that reason, the Federal Maritime Commission is looking to create this year a national data portal to help supply chain managers evaluate port efficiency. In an industry looking to increase transparency in order to provide not only reassurance after Hanjin's failure, but also port value and viability in a shrinking market, demonstrating improved speed and convenience could ultimately be a key to survival.