Dive Brief:

- Experts project that within three years, 80% of 3-D printing will be geared toward finished products, but its capacity to produce small and limited-batch pieces is already threatening to disrupt the spare parts market, Forbes reported last week.

- Companies like Mercedes-Benz, Deutsche Bahn, Siemens and BMW are already using 3-D parts for their products, as computer-aided design (CAD) files save space while expediting the production process at times of greatest need.

- Logistics companies may profit from adopting the technology thanks to the distribution centers, warehouses, and sophisticated inventory management software already in place, providing a gateway to enter an industry projected to generate $400 billion by 2030.

Dive Insight:

Lead times for small or obscure parts can be long and expensive. Sourcing a part can cause delays along the supply chain that cause enough disruption to lose a client. The ability to self-source via 3-D printing can save a company countless days and dollars, even when small manufactures are able to ship a part on the spot.

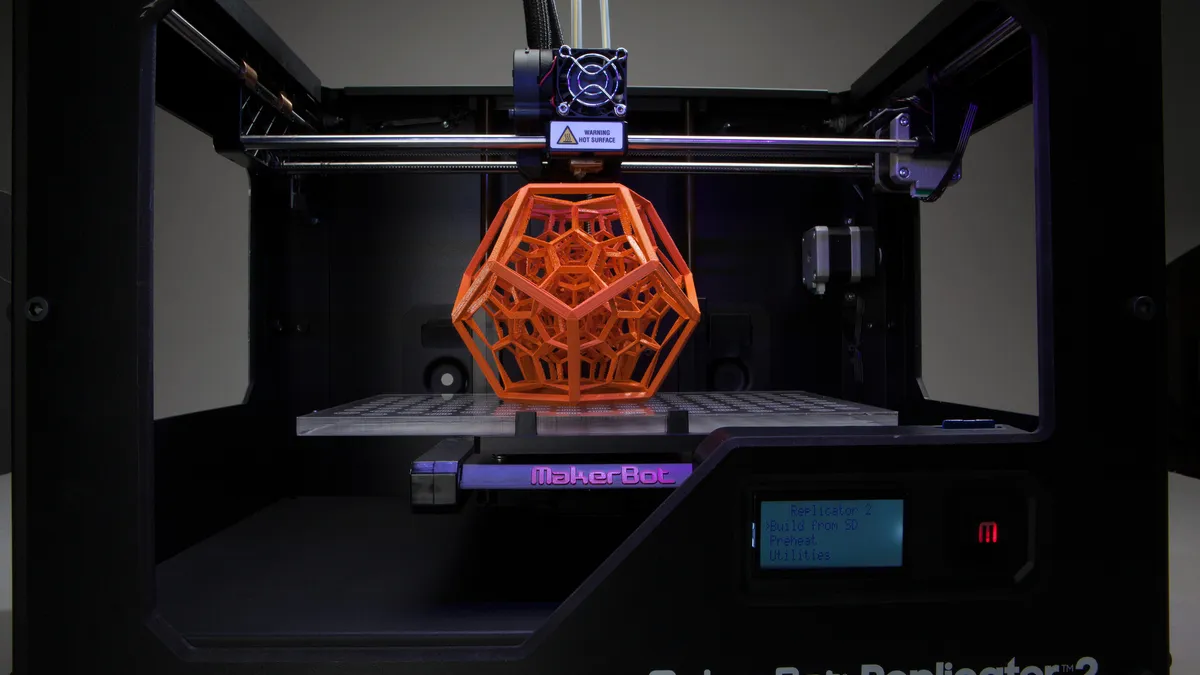

What 3-D printing provides is a turnkey solution. Through access to CAD files that take up less space than a warehouse, a seller can create a necessary part in minutes rather than wait the days or hours needed to expedite one from a supplier. It can also become its own source provider if it has the capability to print in other mediums such as metal.

A 3-D printer can also help mitigate disputes caused by shipping interruptions, such as what occurred at Volkswagen in August of 2016. A contract conflict caused suppliers to simply stop shipping parts to the German automaker, forcing delays on a company still recovering from an emissions scandal. Had VW been able to create its own parts, no disagreement would have occurred.

Seeing the potential for 3-D printing as a service, UPS continues to expand its UPS On Demand service, which makes the technology available to manufacturers within 24 hours. Currently, the service is mainly used for prototypes, but the Forbes article suggests the model could be used for spare parts delivery as well. In the case of UPS, the logistics provider's global network allows it to promise that 24-hour service through various production facilities.