Dive Brief:

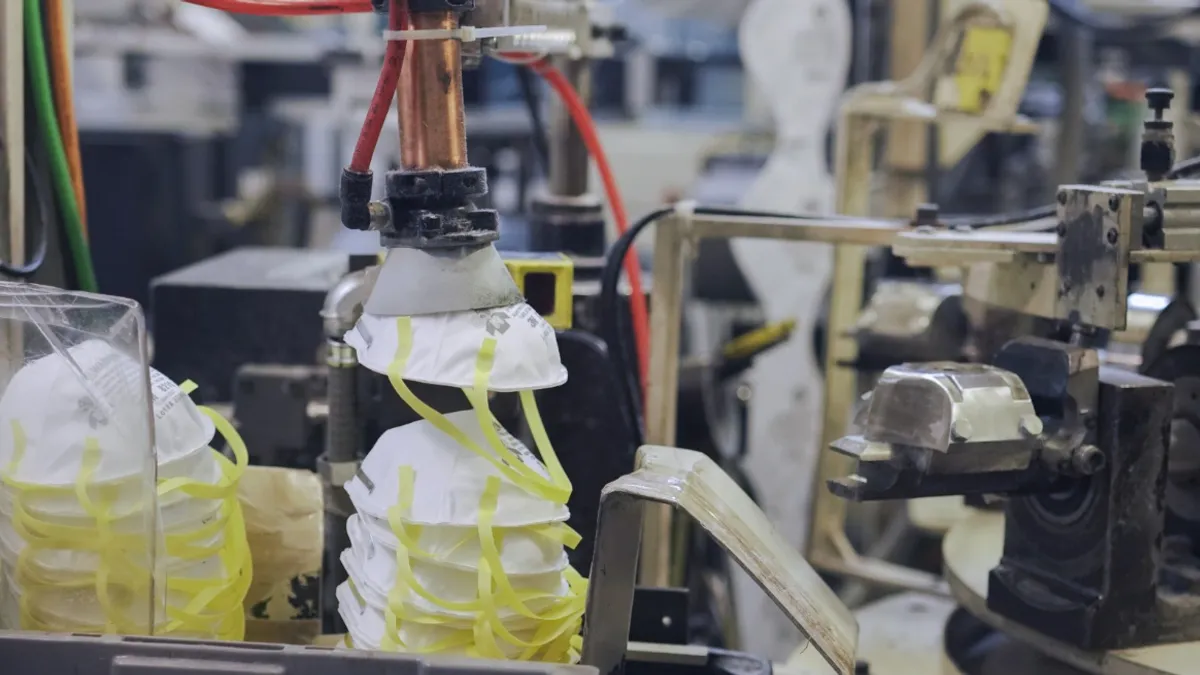

- 3M has increased its annual production rate to 2.5 billion N95 respirators, a fourfold increase over 2019, executives said on their Q4 earnings call Tuesday. In 2020, the company produced 2 billion respirators globally.

- The company's ability to expand production of personal protective equipment is thanks, in part, to 3M's agile supply chain and shorter cycle times, CEO Mike Roman said on the call.

- Roman said production lines are operating at full capacity as 3M anticipates continued strong demand for respirators.

Dive Insight:

3M is one of many PPE manufacturers that ramped up production to meet pandemic-induced demand. Last January, 3M activated surge capacity, idled since the SARS outbreak in the early 2000s, to increase output of N95 masks. By the end of the year, it had manufactured 2 billion respirators globally.

"You can see the work the supply chain teams have done to keep our supply chain lines running despite supply chains in general being broken," Monish Patolawala, senior vice president and chief financial officer at 3M, said on the call.

3M received a $76 million contract from the federal government last April under the Defense Production Act to increase N95 production. The company added 120,000 square feet to its largest U.S. respirator plant, located in South Dakota. The expansion "was made possible by a partnership with the U.S. Department of Defense along with investments by 3M," said 3M.

The Biden administration has also invoked the DPA, though the White House has not yet said to which companies it will grant contracts.

"Our work is ongoing with companies to ensure that we are expediting the manufacturing of materials to ensure that we can get 100 million shots in the arms of Americans," White House Press Secretary Jen Psaki said at a Wednesday briefing. She named examples such as syringes, N95 masks, gowns, gloves and pipette tips.

On 3M's earnings call Roman noted "productive conversations" and "open lines of communication" with the Biden administration related to COVID-19 response.

When executives and analysts familiar with the company speak about what made 3M's pandemic response possible, they come back to the core tenets of supply chain planning.

The manufacturer transitioned from sales and operations planning to integrated business planning about three years ago, Mike Burkett, a vice president and distinguished analyst for the Gartner Supply Chain team, said in fall 2020. Last January, 3M announced a new operating model, putting manufacturing, supply chain and customer operations under one umbrella.

"We saw the benefits come in our ability to respond to just the dynamics that we hit," Roman said of the new model, adding that it's allowing 3M to better use real-time data and shorten its cycle times.

3M worked with visibility and software company FourKites before COVID-19, but during the pandemic, it added critical shipments to the FourKites system so real-time data was in one spot.

"There's data democratization, where we can see stuff that is happening much faster on a daily basis," Patolawala said. "There's much more transparency on issues that we are facing, and the team is going in eyes wide open and trying to find solutions as quickly as we can."