Dive Brief:

- Ford is leaning on expedited shipping lanes to pull ahead supply and mitigate COVID-19 disruptions in China, President and CEO Jim Farley said during the carmaker's Q1 earnings call.

- The company secured fast maritime shipments as well as "airlift capacity to protect our suppliers," said Chief Industrial Platform Officer Hau Thai-Tang during the call.

- Speeding up shipments and other steps to secure supply have come at a cost. "We, obviously, are spending a lot of money on premium freight and other things to work around COVID escalations in China," Farley said.

Dive Insight:

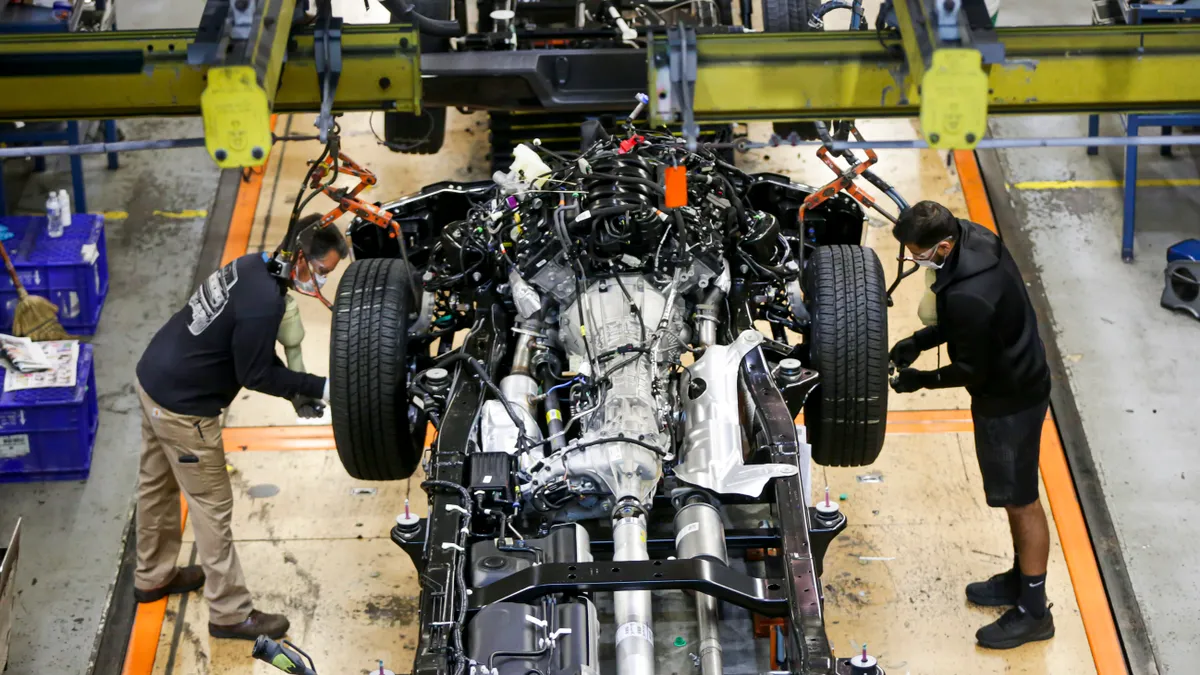

Ford, which has 50 Tier 1 suppliers in China, is working to restart production in the country as manufacturing in major cities such as Shanghai remains snarled by COVID-19 lockdowns. Authorities in China are "just starting to have a white list process to allow suppliers to resume production," said Thai-Thang.

Shanghai's "white list" is its system of prioritization for companies that can receive approval from local authorities to resume production. Authorities initially prioritized approving many automotive companies, which must prove their factory campuses can comply with the city's stringent virus-control measures.

The company's suppliers in Shanghai are facing limited capacity as a result of the lockdown restrictions. To "protect" its suppliers, the auto company has "secured fast maritime shipments," said Thai-Tang. "So we're working with our teams on the ground in China to help those suppliers get partially operational," he said during the April 27 call. Ford could not be reached for updated information related to the state of their suppliers' operations.

Ford isn't the first to use faster trade lanes to secure on-time delivery. Using expedited shipping lanes has been gaining momentum among some shippers as a way to help secure shipments and gain both reliability and stability. Expediting freight can give companies an edge because they can bring product to market that much faster, said Craig Grossgart, senior vice president of global ocean product at SEKO Logistics.

Supply constraints slowed down Ford's vehicle assembly during Q2, with more than 50,000 vehicles awaiting component installations, Lawler said. Semiconductor-related commodities have been "hamstringing us," Farley noted.

Ford anticipated the shortage of semiconductors "to get worse before supply levels improve," said Farley during last year's Q1 earnings call.