Editor's Note: The following is a guest post by QAD President, Founder and Chairman Pam Lopker.

As the Trump administration continues to evaluate the U.S. economy, and begins devising policies that address pressing issues such as sustainable production growth, ongoing job creation, skilled labor shortages, and rapidly-changing technologies, many economists have speculated about the short- and long-term future of American manufacturing.

Will the U.S. remain competitive with other G7 nations? Can the country recapture its global manufacturing leadership? Can we hold on to (or even bring back) jobs and facilities instead of offshoring them? Will advances in automation result in further job losses? Will we ever have a trade surplus again?

These are fair questions to ask, especially since their answers have acute trickle-down effects to manufacturers operating in many industries.

The truth? America’s manufacturing demise has been greatly exaggerated. In fact, it’s enjoying a resurgence — some have even described it as a Renaissance — fueled by tremendous progress in automation, engineering, and quality management, that is pushing domestic producers to the top once again.

As a result, the future of American manufacturing is now, and the outlook for the next several years should be filled with optimism … albeit tempered with caution.

Today’s manufacturing environment, and whatever form it ultimately takes in coming years, bears little resemblance to the production climate of previous decades. Consider the following developments, all of which are now playing out with American manufacturers of all sizes, and which will continue to evolve during the current presidential administration and beyond:

Economic indicators show manufacturing is on the rise

The U.S. manufacturing sector is poised for moderate growth in the current fiscal year, as consumer spending continues to rise.

According to the Commerce Department’s latest report, gross domestic product (GDP) increased 1.9% in the final quarter of 2016, while output increased 3.5% in the third quarter. Overall, the U.S. economy grew 1.6% for all of last year. While these figures aren’t exactly robust, they still represent economic growth, not decline.

In more encouraging news, consumer spending, which accounts for more than two-thirds of all U.S. economic activity, rose 3% in the fourth quarter. Increases in consumer spending point to elevated demand for durable and non-durable goods, and those signs are always reassuring to manufacturers.

Many entities, including the Organization for Economic Co-operation and Development (OECD), have predicted U.S. GDP will grow 2% to 3% in 2017. Several manufacturing indices were also on the rise this year, according to the Institute for Supply Management (ISM). Anecdotally, I’ve heard from many of my company’s U.S.-based customers, and others with large operations here, and most expect moderate growth in 2017 and throughout the remainder of the decade.

Today, many economists are shifting their attention to the White House, which is formulating major economic policy proposals that could potentially accelerate growth across several major economic indicators. More specifically, the U.S. economy, and its manufacturing sector, could get a much-needed boost from President Trump’s proposed stimulus package of sweeping tax cuts for individuals and corporations, greater infrastructure investment, and fewer government regulations.

As with all things economic, we must wait and see which policies are put in place to determine what precise impact they will have on American manufacturers.

Jobs are returning to the U.S. as offshoring costs rise

Manufacturing jobs are slowly returning to the U.S., but they now require more sophisticated education and capabilities. As a result, demand for more highly-skilled labor will increase, and corporations and government agencies must bridge the skills gap.

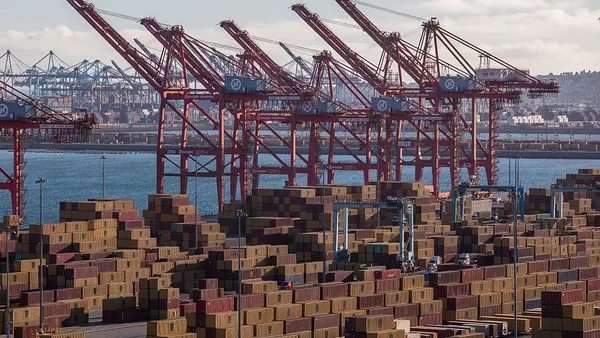

It’s been well documented that labor costs in China and India, once primary offshoring destinations, have risen substantially in the past decade. Logistics expenses to ship finished goods back to the U.S. have also increased, and that adds to their cost of goods sold (COGS) and ultimate retail prices. Therefore, it is no longer as cheap for American companies to fabricate products in those countries.

According to Oxford Economics, China’s labor costs are now only 4.0% lower than those in the U.S., when productivity is considered. Domestically, remarkable employee and shop-floor productivity improvements have kept labor expenditures in check. Consequently, it makes sense for American firms to bring some previously-offshored jobs back home.

After losing manufacturing jobs the past 25 years, the U.S. is finally seeing some of those positions slowly return, a phenomenon known as reshoring. In a recent Washington Post analysis, America has regained nearly 500,000 of six million manufacturing positions lost since 2011. That’s the good news. The bad news? Many returning jobs are not identical to the ones which left, nor are they coming back to the same cities which lost them.

Another complication: many reshored jobs will require new skill sets, and automation will reduce the number of jobs that do come back. When I tour my customers’ plants each year, I see more robots and fewer workers. That’s problematic for manufacturing jobs, but it’s also reality.

American engineers and scientists are hard at work developing the necessary technologies to keep U.S. manufacturing at the forefront of global industry.

Pam Lopker

Founder, President and Chairman, QAD

For America to justify the creation (and the reshoring) of manufacturing positions, it needs qualified personnel to create, install, repair, and manage the wide array of technologies, including robots, used on the shop floors and in the back-offices of today’s facilities. Educated and experienced workers are needed. Unfortunately, there is a dramatic shortage of employees with the technical expertise to fill many reshored positions.

Let’s call this what is: a skills gap.

How can we narrow this divide? Corporations must collaborate with universities, and government and non-government organizations (NGOs) to develop timely, relevant programs and curricula which can produce more skilled labor. Going one step further, we must proactively encourage children to study and pursue science, technology, engineering, and math (STEM) careers so they are prepared to assume these roles which American producers are desperate to fill.

It’s important to note this skills gap also affects employment in other industries, not just manufacturing, so further development and hiring of STEM talent is a tide which lifts all boats. For example, my own company, QAD, has faced similar challenges as many of our senior R&D associates retire, so we started a “fast track” program for identifying and hiring STEM majors from top universities. Other companies, in other industries, have implemented similar initiatives, and they have been effective in enhancing the technical experience and knowledge of their respective organizations.

When it comes to bankrolling these initiatives, some have suggested using government revenue from import tariffs, a strategy on the table for correcting America’s current trade imbalance, to finance the education and training of a new generation of skilled laborers. Another solution could lie in private corporate-sponsored initiatives, such as the $1 billion fund which Apple CEO Tim Cook recently announced to promote the creation of U.S. manufacturing jobs.

We’ll see if our political leaders and manufacturing executives can effectively collaborate on solutions which increase the numbers of U.S. manufacturing jobs and skilled workers.

Technology is making our factories more efficient

Automation advances and ongoing technological innovation are converging to create highly-efficient manufacturing facilities which produce higher-quality goods.

As previously mentioned, American manufacturers are now relying on cutting-edge technologies to transform production centers into the most efficient and technologically-advanced facilities on the planet. These exciting innovations include highly-specialized robots, 3-D printing, artificial intelligence-enabled equipment and IT networks, machine-to-machine (M2M) applications, and sophisticated enterprise resource planning (ERP) and other cloud-based software solutions, to name a few. Currently, U.S. producers are leveraging these advances to consistently turn out higher-quality products with more customization options and fewer defects.

This trend will absolutely continue.

For example, as refinements are made with robotics, machines can automatically handle more specific tasks, such as sizing and tightening bolts on automotive assembly lines, or even more complex jobs which require series of multiple steps using numerous parts. With predictive maintenance, breakthroughs now allow plant managers to predict future equipment breakdowns and employ fixes before they are needed. Moreover, ERP software, which lies at the heart of almost every manufacturing operation, can handle more data and M2M capabilities so companies can engage in more intelligent demand and supply chain planning.

As these technologies become cloud-based and connected, manufacturers will have near pervasive, yet simple and accessible, connectivity through mobile devices and web apps to a diverse spectrum of important data, which can be used to make quick, informed operational decisions.

These advances can be found in facilities around the country right now, with improvements being made every day to make U.S. manufacturing more lean, resourceful, and competitive. However, this is just the tip of the iceberg. New needs arise continuously, such as the requirement for easier, faster electronic data interchange (EDI) and the ability to more closely track part usage through passive RFID chips. American engineers and scientists are hard at work developing the necessary technologies to keep U.S. manufacturing at the forefront of global industry. We simply need more of them to keep the American manufacturing sector strong and vibrant.

While the U.S. has its work cut out on different fronts for it to remain a viable, sustainable producer, the future of American manufacturing is now, and we have many reasons to be cautiously optimistic about its outlook in the coming years.

Pam Lopker is the founder, president and chairman of Santa Barbara, Calif.-based QAD, Inc. (NASDAQ:QADA/QADB), a leading provider of enterprise resource planning (ERP) software and services to global manufacturing companies She can be reached at [email protected].