Dive Brief:

- Seattle, Washington-based Amazon will begin testing a two-legged robot dubbed Digit at its robotics research and development site just south of Seattle, and is initially planning to use them to pick up and move empty containers in warehouses, according to a company blog post last week.

- Digit can move, grasp and handle items in spaces and corners of warehouses. It initial use will be to help employees with tote recycling which is a repetitive process of “picking up and moving empty totes once inventory has been completely picked out of them.”

- The robot was developed by Corvallis, Oregon-based Agility Robotics, one of the companies Amazon invested in through its $1 billion Industrial Innovation Fund as part of a decades-long push to invest in “next-generation technology” in its operations, the company said in 2022.

Dive Insight:

The news comes as CFOs have struggled to navigate an unusually tight labor market. Hiring soared in September by 336,000, exceeding predictions and validating recent signals from Federal Reserve policymakers that they plan to sustain high interest rates for a longer period than forecast in June, CFO Dive previously reported.

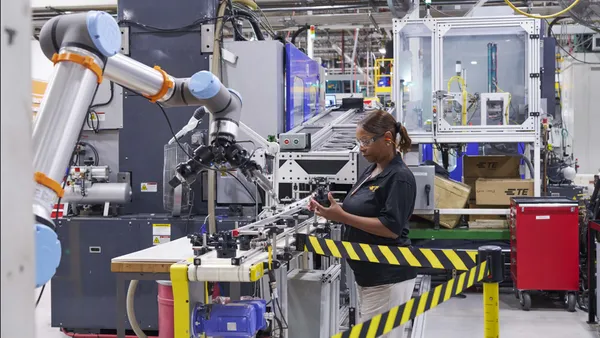

Amazon has accelerated its use of robotics and currently has has over 750,000 robots working with its employees, according to the blog post. In 2022, the e-commerce and delivery giant showcased a series of robot prototypes to improve operational efficiency in its facilities. Proteus, Cardinal and Amazon Robotics Identification are some of the robotic innovations Amazon has deployed throughout its supply chain.

Separately, the company said it also launched a new robotic system at one of the company’s fulfillment centers in Houston, Texas, which will help the company meet holiday demand. Known as Sequoia, “the system works by having mobile robots transport containerized inventory directly to a gantry, a tall frame with a platform supporting equipment that can either restock totes or send them to an employee to pick out inventory that customers have ordered,” the company said.

Last month Agility announced it is building a manufacturing plant in Salem, Oregon, which will be able to produce more than 10,000 robots annually, according to an Agility release.

“Digit is designed from the ground up to go where people go and do useful work, safely, in spaces designed for people,” the release states, adding that initial applications include bulk material handling within warehouses and distribution centers. Digit is expected to be generally available in the market in 2025.

Amazon emphasized the safety benefits of using robots, noting that company data indicates recordable incident rates and lost-time incidents fell 15% and 18%, respectively, in 2022 compared to the prior year. It also noted that it has created “hundreds of thousands of robotics systems while also creating hundreds of thousands of new jobs within our operations.”

Some are concerned about people losing their jobs to the robots. Stuart Richards, a union organizer in England at UK trade union GMB, called Amazon's automation a “head-first race to job losses. We've already seen hundreds of jobs disappear to it in fulfillment centers," Richards said, according to a recent BBC report.

But Damion Shelton, Agility Robotics’ co-founder and CEO, said in a statement in release that Digit would solve workplace problems like “injuries, burnout, high turnover and unfillable labor gaps, with the ultimate vision of enabling humans to be more human.”