Dive Brief:

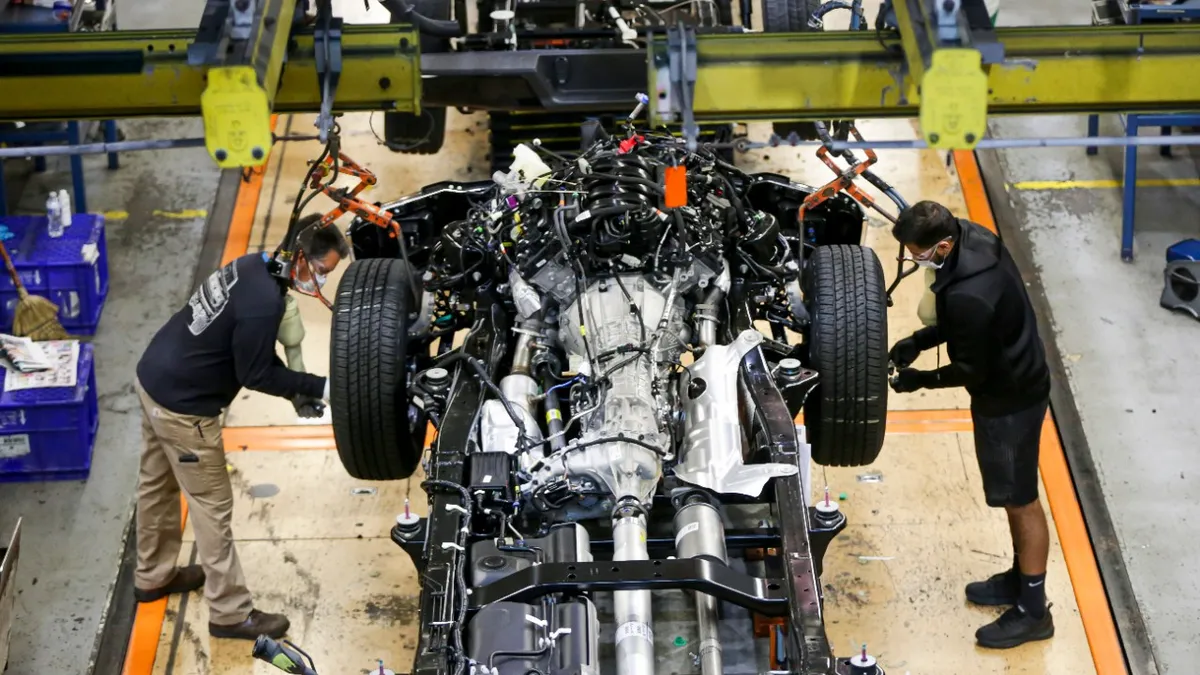

- Ford's Dearborn Truck Plant and Chicago Assembly Plant opened again Thursday after closing earlier in the week for "deep cleaning and disinfecting" as a result of employees at the locations testing positive for coronavirus, a company spokesperson confirmed to Supply Chain Dive.

- One employee at the Dearborn facility tested positive and two at the Chicago location tested positive. "We deep cleaned and disinfected the work area, equipment, team area and the path that the team member took," the company said. The United Auto Workers did not respond to a request to comment.

- Ford resumed production at its facilities on Monday after stopping production in March in an attempt to add "additional protocols and procedures for helping prevent the spread of the virus" in the company's facilities.

Dive Insight:

The closures at the Ford facilities highlight how hard it can be to operate a production facility amid a pandemic as worker safety and supplier relationships become more difficult to navigate. But Ford said "due to incubation time, we know these employees did not contract COVID-19 while at work. Our protocols are in place to help stop the spread of the virus" — showing even if a facility takes precautions to protect its employees, infected workers can still end up at the location.

Lear Corporation, a supplier for Ford and other automotive companies, also halted production this week as a result of a positive coronavirus test at its Hammond, Ind., location, Lear confirmed to Supply Chain Dive.

"The facility has temporarily stopped production for deep cleaning and disinfection, and we have notified our plant team members, UAW partners and our customer," Lear said in a statement.

Lear's closure was partially responsible for Ford's decision to close its Chicago Assembly Plant for a second day earlier this week, according to The Wall Street Journal.

Even once plant managers decide it's safe to reopen, ramping up operations is not as simple as flipping a switch. "Restarting production on this scale is a monumental task, maybe even more challenging by the need to add safety protocols to minimize the potential spread of the virus," Lear CEO Ray Scott said on an earnings call earlier this month.

Daimler also suspended production at its Mercedes-Benz plant in Tuscaloosa County, Alabama earlier this week as a result of issues sourcing materials from suppliers in Mexico.

The industry has been open about the fact that hurdles will remain as locations try to open up, even as protections are put in place. Positive test cases within a factory workforce can halt production at multiple stages in the supply chain. And the just-in-time nature of automotive operations opens the possibility of unexpected supplier disruptions when these stoppages occur.

"Industry disruptions related to COVID-19 pandemic have impacted our operations in all of our major markets, and we expect additional challenges in the coming months," Scott said.