Dive Brief:

- Thanks to a substantial gift from Delta Air Lines, the Delta Air Lines Foundation and the Jacobson Family Foundation, Auburn University is building a bay dedicated to aviation-based RFID technology, RFID Journal reported recently. Altogether, Delta provided $6 million to the school, with $4 million dedicated to Auburn's Aviation program, in addition to the $2 million dedicated to the RFID Lab.

- The new RFID research bay already contains a simulated aircraft cabin seating 42, as well as a baggage-loading area, service hangar space for tool tracking and an area that will simulate an aircraft parts assembly line.

- Funds from the donation will be used not only to expand the new lab bay, but also endow student and faculty research on RFID tags in avionics.

Dive Insight:

RFID's suitability for avionics will likely expand as industry usage standards are established.

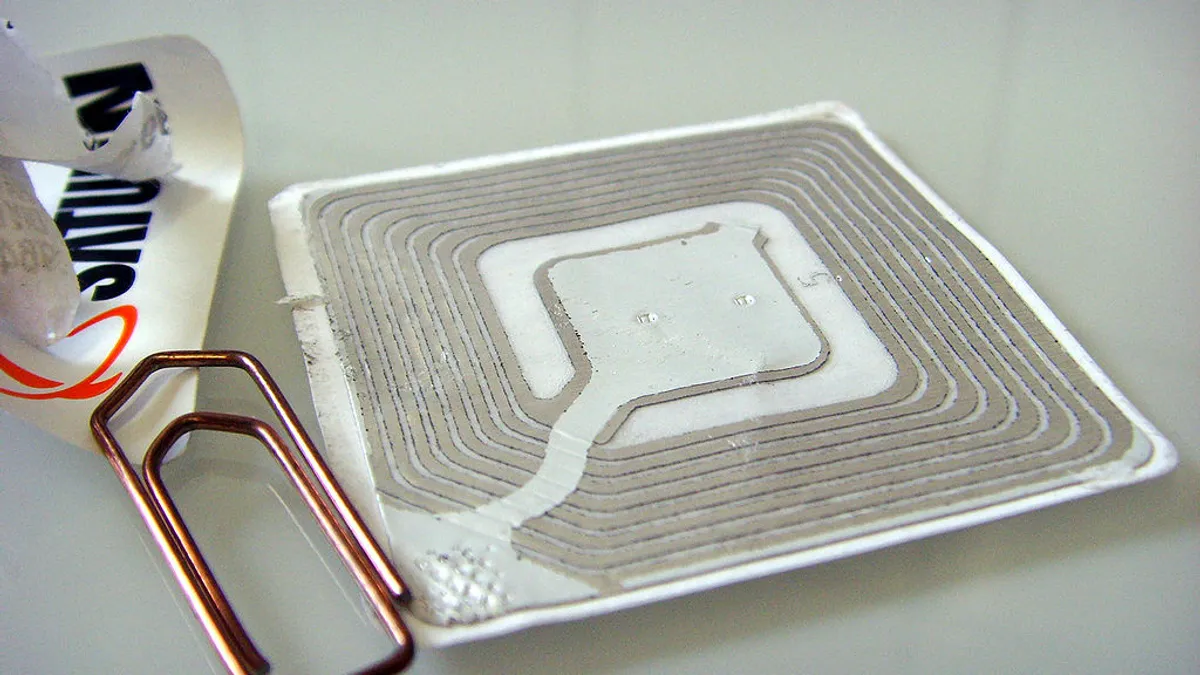

RFID is already stirring the pot within the food industry, allowing for better brand safety and ingredient traceability. Though most commonly applied within retail for better inventory tracking at such stores as Target and Macy's, RFID tags are also appearing as implants within human hands, replacing keys and swipe cards.

RFID's use in aviation is also growing. Baggage tracking is one area where the technology has made an impact.

"Delta has integrated UHF RFID tags into all checked baggage, "said Justin Patton, the RFID Lab Director at Auburn. "This allows more accurate tracking of the bags as they are loaded and unloaded from the aircraft, and they have been sharing this information with passengers in the FlyDelta app."

Flyable parts and safety are also benefiting from RFID technology.

"Many parts go to Maintenance, Repair, and Operations (MROs) for service and maintenance, and an RFID tag is an excellent place to store that data," Patton told Supply Chain Dive. "In addition, airlines often use these tags for compliance programs. Cabin compliance in particular is very popular, as one person can walk down the cabin aisle and verify the presence of all of the tagged safety equipment including life vests, oxygen masks, O2 cannisters, etc. Before RFID this could take hours, as someone had to dig under each seat and scan each item with a barcode one at a time."

Asset and tool tracking are being tagged, too, which is absolutely vital for safety.

"Tracking ground assets, and especially tools, can be helpful from an efficiency and safety perspective in both manufacturing and maintenance, " Patton noted. "Foreign Object Detection (FOD) is a big deal in aircraft manufacture, since leaving a tool in an airplane while it's being built can have grave consequences later. RFID is used by several manufacturers and airlines to scan and locate the tools for safety, and for general accuracy in the check-in / check-out process."