Technology startups are focusing on reducing the empty container problem, a challenge that costs the container shipping industry about $20 billion per year.

At any given time, about one-third of the ocean containers in circulation are empty, and the average container spends nearly half its life idle, according to recent research.

Most major shipping lanes suffer from systemic trade imbalances — more loads flow from producing areas such as Southeast Asia into consuming regions like North America and Europe.

Historically there have been fewer loads going back from the West Coast of the United States to China, to reposition containers for the next round of eastbound shipments. Containers pile up in ports such as Hamburg, waiting to be moved back to Karachi, for example.

The majority of costs come from relocating empty containers thousands of miles back to an origin point.

"You will always need to move empty boxes into China from Europe, from Australia and the U.S. and there's nothing really you can do about that," Christian Roeloffs, one of the founders of Hamburg, Germany-based xChange, an empty container matching service, told Supply Chain Dive. "You cannot avoid the whole $20 billion cost, but you can avoid about 30% of it because this amount is caused by inefficiencies."

Empty containers clog ports

Just how bad is the empty container problem?

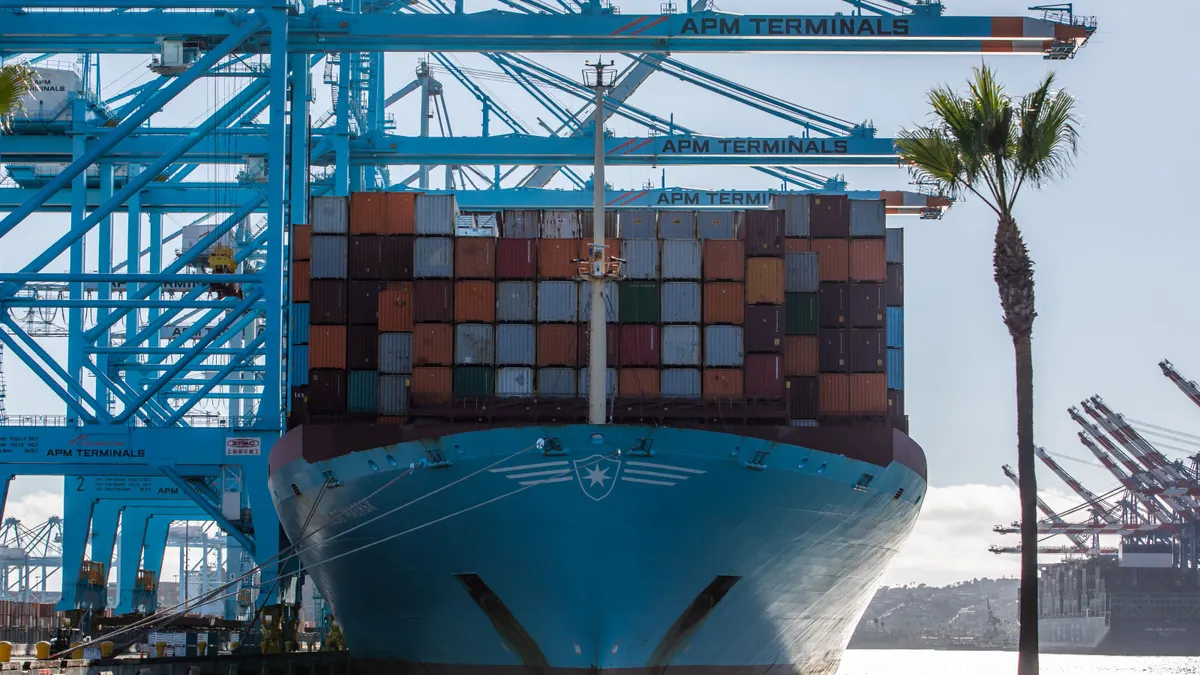

For major U.S. ports, more than half of outbound TEUs moves are empty. At the Port of Los Angeles, the busiest North American port, 57.7% of outbound TEUs in 2017 were empty, according to Port Tracker data from the Pacific Merchant Shipping Association's July West Coast Trade Report. From 2010 through 2017, empties through Los Angeles increased by 35.2%, while loaded TEUs increased 13.8%. The story was similar at Long Beach, where container volumes grew 13.7% from 2010 to 2017, but empty containers grew by 40.6%.

East Coast ports were not immune to the problem. For example, at the Port of New York/ New Jersey, container traffic grew 11.8% while empty traffic increased 58.5% from 2011 through 2017.

Disruptions to traffic flow can exacerbate the issue. When South Korean carrier Hanjin Shipping declared bankruptcy in 2016, containers piled up at ports in Southern California. Terminal operator Total Terminals International brought in a container ship to move 4,300 empty containers back to Asia, out of an estimated 6,000 Hanjin-leased boxes in the region.

In July, the Nigerian Port Authority blocked access for Maersk Line and Cosco Shipping to terminals in Lagos for ten days due to the buildup of empty containers, The Maritime Executive reported. Lack of space for empties led to truck backups at the port, upsetting local residents. During the ban, 19 vessels were likely delayed.

Technology cuts through the knot

One way to cut empty container moves is to send them directly to the next load rather than ship them back to a hub.

The shipping industry is a relationship business, due to the army of personnel at carriers, freight forwarders, container traders and leasing companies tapping their personal network of contacts using phone, faxes and emails to secure loads for empty containers to cover at least a portion of the costs of relocation.

Technology is beginning to tackle the problem. Launched in 2017 as a spin-off of Boston Consulting Group, xChange created a neutral online market of empty containers that members can use to match loads and third-party equipment for one-way container moves.

"The benefit of the platform is that you are not limited to your personal network, you can engage with more than 200 companies right now," Roeloffs said. Users sign a multi-party interchange agreement that speeds up the contracting process by days or weeks.

xChange has more than 200 users on its platform, including ocean carriers, container leasing companies, container traders, non-vessel-operating common carriers and some shippers. The service covers 2,500 locations worldwide and plans to add more hinterland locations.

Users set their own rates and terms and conditions such as the container value and damage protection plans. Users search the listing for containers in locations where they are needed and with a destination close to where the container owner would like the boxes to end up. Over time the system learns an individual's search patterns.

"Once the system gets to know the customer, we can approach them proactively," Roeloffs said.

Other technology companies are tackling the problem as well.

The Port of Rotterdam has developed InlandLinks, an online depot tool. The tool shows empty containers available for use from where their current location rather than moving the container back to a hub or depot before being sent out for a new load.

Antwerp, Belgium-based Avantida developed reUse, a triangulation service that CMA CGM and Hapag-Lloyd recently signed up to use the program in Mexico, the first outpost in North America. A triangulation system manages containers within a transport company. For instance, if a carrier sends loaded containers to Hamburg, the triangulation service identifies a need for empty containers in Wolfsburg rather than them repositioning the container to Hamburg.

With the program, container users can request the liner shipping company directly move an unloaded import container for another load.

"Using an import container to go straight to your export customer without having to go back to the terminal is an advancement for planners and dispatchers," Kapil Garg, head of Inland Operations Latin America at CMA CGM, said in the announcement.

The direct move avoids waiting times at depots and terminals and eliminates unnecessary truck mileage, reducing transportation costs and the environmental impact of trucking. Avantida has expanded the platform to 12 countries, with almost 4,000 registered companies and an average of 1,600 transactions each day.

China's recycling ban worsens imbalance

One of the few bright spots in the empty container imbalance dimmed when China banned importation of many common waste products for recycling. In 2016, China imported some 45 million metric tons of scrap metal waste paper and plastic, according to The Economist.

That trade essentially stopped when Beijing banned imports of 24 types of solid waste, and with bans on additional products going into effect in 2018 and 2019. The current prohibitions include paper and plastic waste steel and used auto parts. Pulp and waste paper were the single largest category of exports from the U.S. to Asia. Losing that trade has made it even more challenging to fill Asia-bound containers, particularly from the U.S.

While technology can make a dent in the empty container problem, completely overcoming trade imbalances is beyond its capability to solve.

"We can increase transparency of information for all parties, but if there is no demand in a specific region, we cannot create demand in that region," Roeloffs said.