Dive Brief:

- After initial reluctance, President Donald Trump on Friday afternoon invoked the Defense Production Act to "compel General Motors to accept, perform, and prioritize federal contracts for ventilators" in response to the COVID-19 outbreak. He said invocation of the Korean War-era law "should demonstrate clearly to all that we will not hesitate to use the full authority of the federal government to combat this crisis."

- While healthcare providers on the front lines of the outbreak and state governors strongly support use of the DPA, the Advanced Medical Technology Association (AdvaMed) says it is wary of invocation of the federal law.

- "Moving forward without DPA continues to be the best course of action," said Scott Whitaker, CEO of AdvaMed, during a Friday press briefing that preceded Trump's decision. The medtech group said it has concerns the law will strain the supply chain and suggest to other countries "that they should limit their own production and exports."

Dive Insight:

The industry's stance puts it at odds with major healthcare provider groups, including the American Hospital Association, American Medical Association and American Nurses Association, all of which urged Trump more than a week ago to immediately use the law to increase domestic production of medical supplies and equipment.

Under the DPA, the president can require companies to prioritize and accept contracts for materials and services to promote the national defense, as well as incentivize the domestic industrial base to expand the production and supply of critical materials and goods.

Trump said in a tweet on Friday that he invoked the law, citing frustration with General Motors over costs, schedules and quantities.

GM is collaborating with Ventec Life Systems to expand ventilator production, with the device maker tapping into the automaker’s logistics, purchasing and manufacturing expertise. But, according to Trump, sufficient progress was not being made, requiring executive intervention.

A spokesperson for the automaker declined a request from MedTech Dive to comment on the action and Trump's criticism. "Our focus is on executing our plan," the spokesperson said.

Ventec was not immediately available for comment. However, Ventec CEO Chris Kiple told NBC News on Friday his company and GM were already well on their way to producing thousands of ventilators before Trump invoked the DPA: "We're moving forward as fast as we can. We understand the urgency around this. We are moving full steam ahead."

Trump also said on Friday that his administration is “working to sign contracts immediately” with major ventilator manufacturers, including GE Healthcare, Hamilton, Hillrom, Medtronic, Philips, ResMed, Vyaireand Zoll, with the goal of delivering 100,000 additional systems over the next 100 days.

However, a spokesperson for Hillrom told MedTech Dive the DPA has not been invoked by the federal government in its dealings with the company. "We have received a notice to proceed and are finalizing the contractual details," a company spokesperson said.

Likewise, a spokesperson for GE Healthcare said so far the DPA has not been applied to its production of ventilators.

Medtech vs. non-medtech

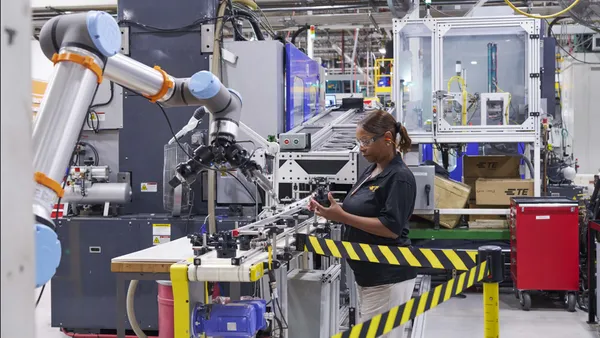

Whitaker praised the administration on Friday for opening up a "fast track" for automakers and non-medtech manufacturers to repurpose their production facilities to produce ventilators.

At the same time, he warned "what we have to make sure of is that as new manufacturers get into the ventilator business they don’t overstress the supply chain" of component parts as well as raw materials. Given the "broad number of component parts that go into a ventilator," Whitaker contends the impact of the DPA could be "crippling."

ResMed told MedTech Dive it has serious concerns about such companies pitching in.

"We welcome non-ventilator manufacturers' help to build and distribute parts for ventilators, not the ventilators themselves," said a ResMed spokesperson. "Specialized ventilator manufacturers are best positioned to produce effective, clinically tested devices quickly; our top obstacle is the scarcity and increasing cost of ventilator parts. Therefore, non-ventilator makers can help most by making parts, not taking them."

Whitaker suggested automakers and other companies outside the medtech industry could focus on "less complicated" manufacturing for "lower level" production ventilators.

He said ventilator makers are adding third shifts and running existing >production lines around the clock, in addition to repurposing production lines and working with companies in other industries to boost the supply of ventilators.

Whitaker noted the FDA’s relaxation of regulations around ventilator manufacturing has made it easier for firms to scale up production."Companies are able to now modify hardware and software in real time without submitting that for premarket notification," he said.

In addition to ventilator production, AdvaMed has weighed in on the distribution of these critical breathing devices. Last week, the group sent a letterto FEMA asking for the designation of a single federal agency to make allocation decisions to ensure ventilators get to those who need them most. "If they’re focused on that, we can focus purely on production," Whitaker said.