Dive Brief:

- More robots were ordered in North America last year than ever before, reaching 34,606 robots valued at $1.9 billion ordered throughout the region, according to the Robotic Industries Association.

- Both orders and shipments grew at a 10% rate compared to 2015. In the fourth quarter alone, over 10,000 robots were ordered, marking an 18% growth rate from the same period in 2015.

- The food and consumer goods industries saw among the largest spikes in orders, ordering 32% more robots in 2016 than the previous year. Food safety inspections, packaging, picking, handling and palletizing were among the highest applications for these robots.

Dive Insight:

Industrial robots have long been part of manufacturing and other production heavy industries, and the trend is set to continue. While food and consumer goods may have seen one of the largest industry spikes, the largest growth applications for industrial robots were in assembly (61%) and spot welding (24%), showing production remains among the largest needs in materials handling.

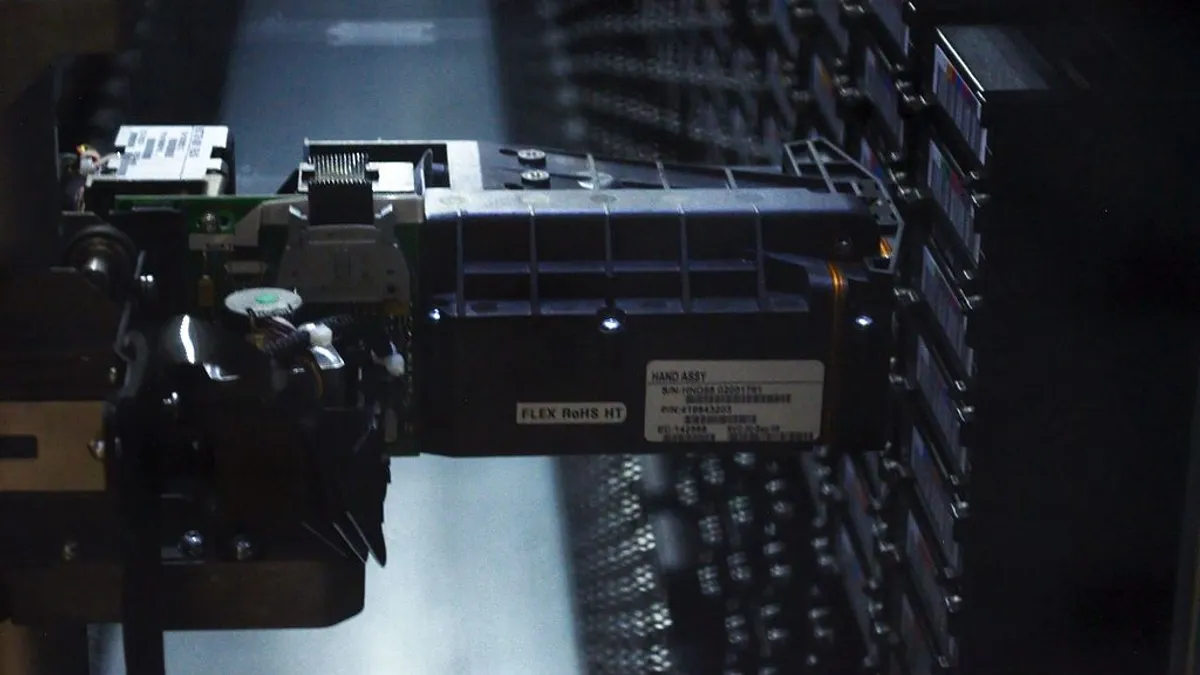

Inspections, packaging, picking and handling were common applications for robots in one industry point to a deeper trend in why people employ robots: to automate rote tasks and, ideally, free up resources for more complex tools. The term "robots" may sound futuristic, but it really points to the robotic arms of old and other sorting machines seen in any manufacturing plant. In other words, more robots may have been ordered and shipped in 2016, but that does not mean they are en masse replacing human jobs.

And if they are, the main question to ask is whether the displaced employees are being retrained to more complex tasks, or not. This question points to a larger story not fully told by measures of robotic orders. That is, as automation takes over rote tasks, the skill sets required for employment are increasing as well.

In fact, hybrid production plants, warehouses and even office analytics firms will become not just common, but necessary, as the world adapts to a higher rate of general production. Think of analytics platforms, or even excel, as robots — the platforms take over rote tasks, but require a human with specialized skills to transform the insights into actionable tasks and data. The role of the supply chain manager, or production manager, or warehouse manager working alongside robots, then, is to innovate and add value.