Dive Brief:

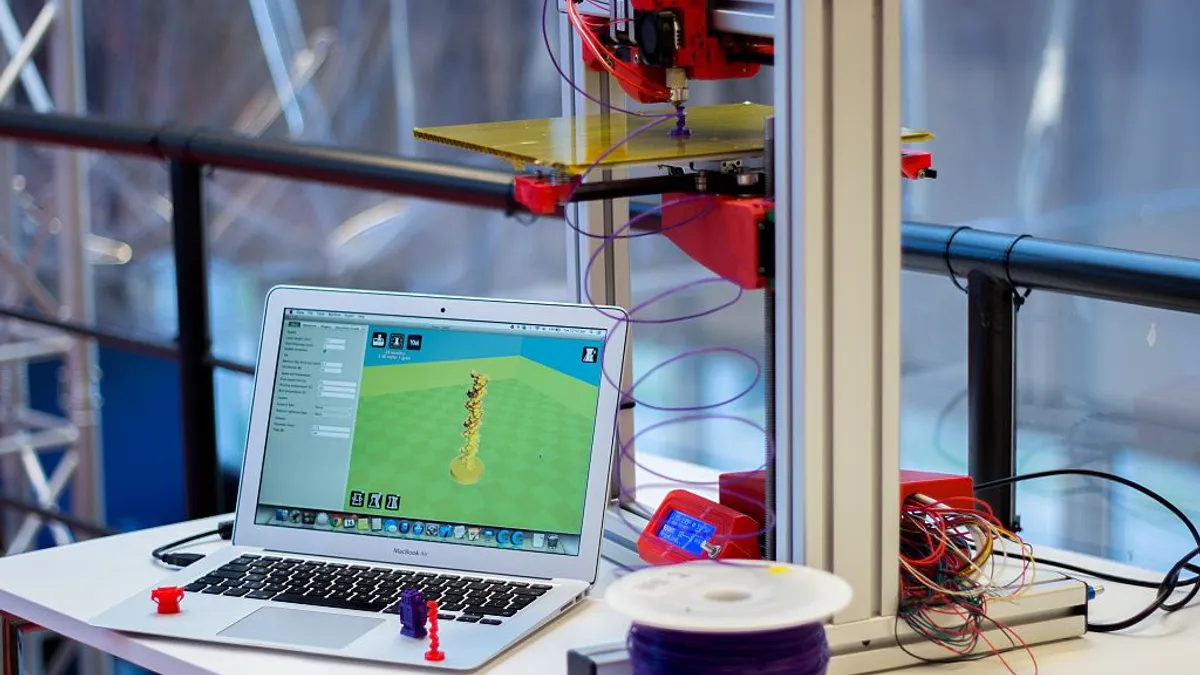

- SAP SE intends to streamline its manufacturing supply chain and internet of things (IoT) options with UPS, HP, and Jabil Circuit in order to provide a quicker means of accessing 3-D printing opportunities, DC Velocity reported.

- Customers are now able to log into SAP Distributed Manufacturing, upload an image of the item they intend to print, and then will have the ability to access UPS' shipping to send the finished product directly to a client.

- The ability to print on demand could provide companies with a less costly means of managing short production and prototype manufacturing, all while reducing inventory storage.

Dive Insight:

SAP is one of the strongest promoters of 3-D printing technology, first with its innovations labs, and now with its easy to access printers, while UPS is an early adopter. Their current partnership could have a lasting effect on the supply chain by significantly reducing supplier involvement in prototype creation — and beyond.

SAP is taking advantage of its integrated platforms to normalize 3-D printing with its procurement process. The SAP Distributed Manufacturing application works hand-in-hand with SAP S/4HANA, a purchasing and contracting application, to develop orders, while counting on UPS' logistics network to fulfill them.

At present, UPS customers such as camera-maker GoPro, the ergonomic furniture manufacturer HumanScale, and gear box maker Stober Drive are employing the technology to create actual parts. In September, Singapore became host to a 3-D printing facility associated with UPS On Demand, demonstrating its commitment as an early adopter and expanding global access.

UPS is highly enthusiastic about the process, and expects it to soon see industrial use in the form of customized valves, replacement parts for military aircraft, and automotive parts.