Dive Brief:

- Spirit AeroSystems, Boeing's largest supplier, has completed a warehouse consolidation effort years in the making at its Wichita, Kansas, campus, CEO Tom Gentile said on the company's earnings call Tuesday.

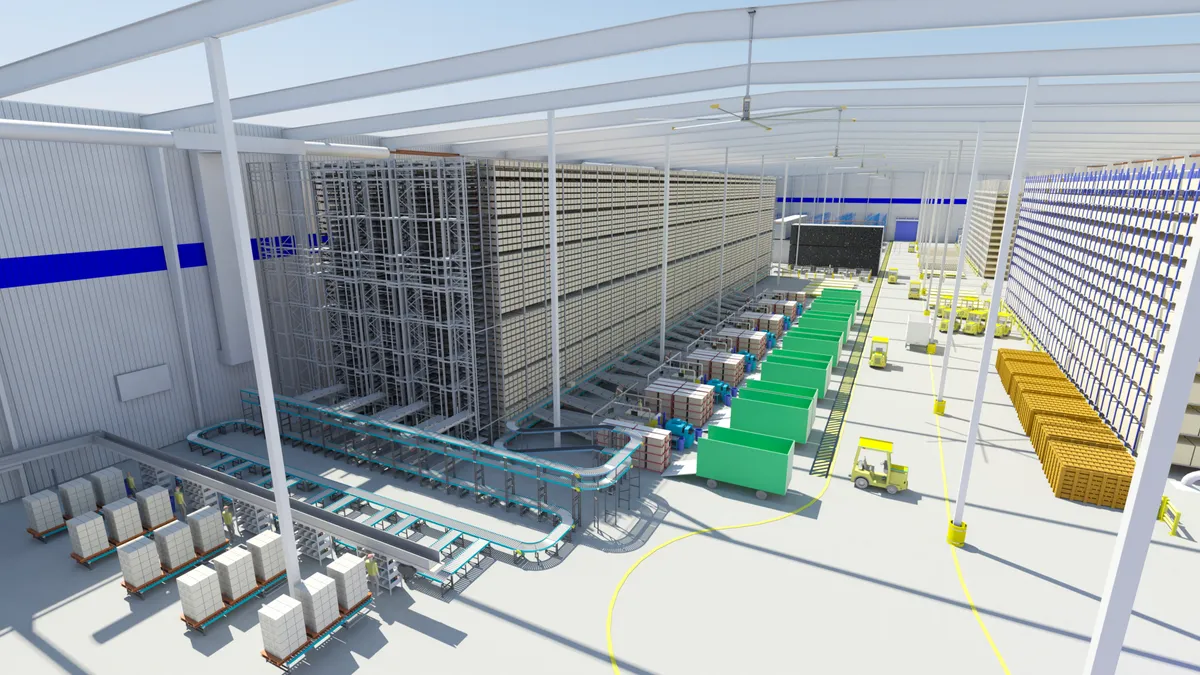

- The new Global Digital Logistics Center brings what was 500,000 square feet of warehouse space into a seven-story 150,000-square-foot facility, Gentile said.

- "We have leveraged technology, similar to what other world-class distribution centers use, which translates into a more accurate and timely part handling and delivery system to the mechanics building product on our factory floor," he said.

Dive Insight:

Spirit AeroSystems announced it had broken ground on the new logistics center in 2018, noting that it will help to increase storage capacity and the efficiency of retrieving parts, according to a press release from the time.

Business has slowed at Spirit AeroSystems. The number of shipsets the supplier delivered dropped from 1,791 in 2019 to 920 in 2020, according to slides presented during the earnings call.

"Almost immediately in 2020, we started with the need to react to multiple production rate reductions, due to the 737 MAX grounding and then the COVID pandemic impact," Gentile said.

The upside of the slowdown in demand in the aerospace industry is it gave Spirit AeroSystems time to focus on productivity improvement projects, like the logistics center, more than it could have at higher production levels, Gentile said.

"We've now started to really completely overhaul the flow," he said. "We couldn't have done that if we were at 52 aircraft per month. But at seven aircraft per month, we had the capacity to do it, and we went and did it."

When production levels pick up again, the logistics center is expected to improve production flow time, according to the 2018 press release. It will handle about 51,00 parts, according to the Wichita Business Journal.

Another efficiency project the company undertook was an automated assembly line for the 737 Max floor beams.

"A MAX eight has 47 floor beams, with more than 400 different configurations," Gentile said. "This new assembly line will improve quality and our ability to manage all of these configurations. It will be operational by the end of this quarter."

Automation is driving warehouse productivity across industries, and Prologis estimates a decreasing need for supply chain real estate as facilities become more efficient.

In a customer case study, DHL said it worked with a medical company to consolidate two warehouse locations into one, which resulted in a 29,000-square-foot cut to the operational footprint and a 3.4% to 4.7% reduction in logistics costs. DHL noted that this kind of consolidation also involved overhauling the company's technology systems including warehouse management, transportation management and ERP systems.

Gentile said Spirit AeroSystems uses the metric of realization — the number of units produced in the available time — to measure the success of automation, robotics and digitization efforts. The improvements are expected to help the company reach 90% to 100% realization, he said.

It also expects to see improvements in quality and labor productivity as a result of the tech investments.

"We're expecting overtime to be less than 8% going forward," Gentile said. "We had time periods in the last couple of years as rates were going up where overtime could even reach into the 30% range. So that's going to be a significant reduction."

The downturn in business from customer Boeing resulted in Spirit Aerosystems needing to find cost savings. The supplier has reduced its commercial aviation program headcount by more than 8,000 people. But it also noted that Boeing, its largest buyer, has stepped in with some financial assistance in the form of a $225 million advance.