Dive Brief:

- Temperature control and cold chain innovation is the number one priority in a survey of 450 industry leaders, according to DHL's Top Ten Trends in the Life Science and Healthcare Supply Chains report, sent to Supply Chain Dive via email. Supply chain digitalization and data analytics came in second, while cost efficiency and service level optimization came third.

- Temperature control and cold chain have repeatedly ranked as a top concern, according to DHL. For the past decade, the industry has been focused on improving cold transport, packaging and tracking technologies to enhance supply chain visibility and sustainability, Larry St. Onge, president of Life Sciences and Healthcare at DHL Customer Solutions and Innovation, told Supply Chain Dive.

- While firms are looking to make their cold chains more efficient by investing in these innovations, St. Onge said, the FDA's serialization requirement, requiring traceability of all drugs in the supply chain by 2023, is another motivating factor. Retooling packaging and the cold chain logistics process not only enables firms to improve their operations but to build in new technologies to better verify and track product moving through the supply chain.

Dive Insight:

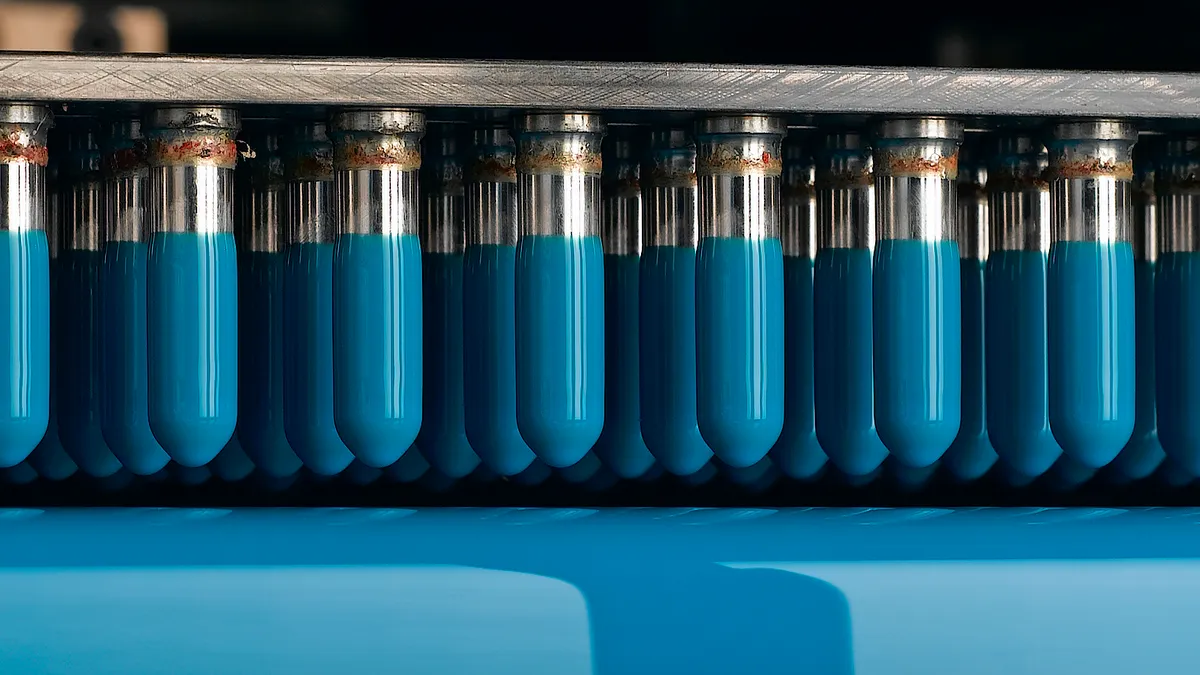

Complex biopharma products like gene therapies often need to be transported in closely controlled environments and with constant monitoring to ensure they are safe for healthcare providers and patients to use. If these measures fail, healthcare firms can lose millions of dollars in product.

This is particularly a challenge for companies moving product via air and ocean freight, St. Onge said, where temperatures are hard to maintain and container-level visibility can be very low because cargo changes hands so many times.

For these reasons, the industry has focused on developing packaging solutions that insulate medical cargo and control its temperature while using less energy (self-cooling units can require a significant amount of electricity) and more sustainable materials. St. Onge said he was unable to get into specifics about these designs as DHL is currently working on them with private customers, however, he said firms are also using this opportunity to build visibility solutions, like Internet of Things (IoT) technology, into product packaging to constantly track temperature, location and quality.

Similar measures have started taking off among freight carriers, with CMA CGM, Hapag-Lloyd and MSC installing IoT sensors on thousands of containers over the past year. The sensors offer shippers additional insight into the location, temperature and flow of goods, helping to reduce costs due to lost inventory or other complications that might have been harder to forecast beforehand.

This is important for drug manufacturers as the security and verifiability of their product from end-to-end is crucial. Experts estimate hundreds of thousands of deaths per year are attributable to counterfeit drugs infiltrating global supply chains, particularly in developing countries.

To prevent this, and meet the FDA serialization deadline, firms are focusing on leveraging blockchain, digital twin technologies and other solutions as an added measure to secure and verify drugs from origin to patient. St. Onge believes this will become increasingly critical as highly-sensitive, and expensive, biopharmaceutical products like gene therapies and "orphan drugs" for very rare diseases become more prevalent on the market.