Dive Brief:

- UPS led a $48 million series B funding round for 3D printing startup Fast Radius. UPS has been working with Fast Radius since early 2016, and the 3PL has participated in two previous rounds of funding for the company via the UPS Strategic Enterprise Fund, a UPS spokesperson told Supply Chain Dive in an email.

- "Additive manufacturing is increasingly becoming the logical direction for future supply chain strategies, blurring the lines between physical and virtual warehousing for products in many industries," Scott Price, the chief strategy and transformation officer at UPS, said in a statement. "Fast Radius’ technology platform and additive manufacturing design processes are bringing the virtual warehouse vision to life for their customers, complementing UPS’ global time-definite logistics expertise."

- The funding will be used to expand Fast Radius' global footprint and scale up its software development, application engineering and sales teams.

Dive Insight:

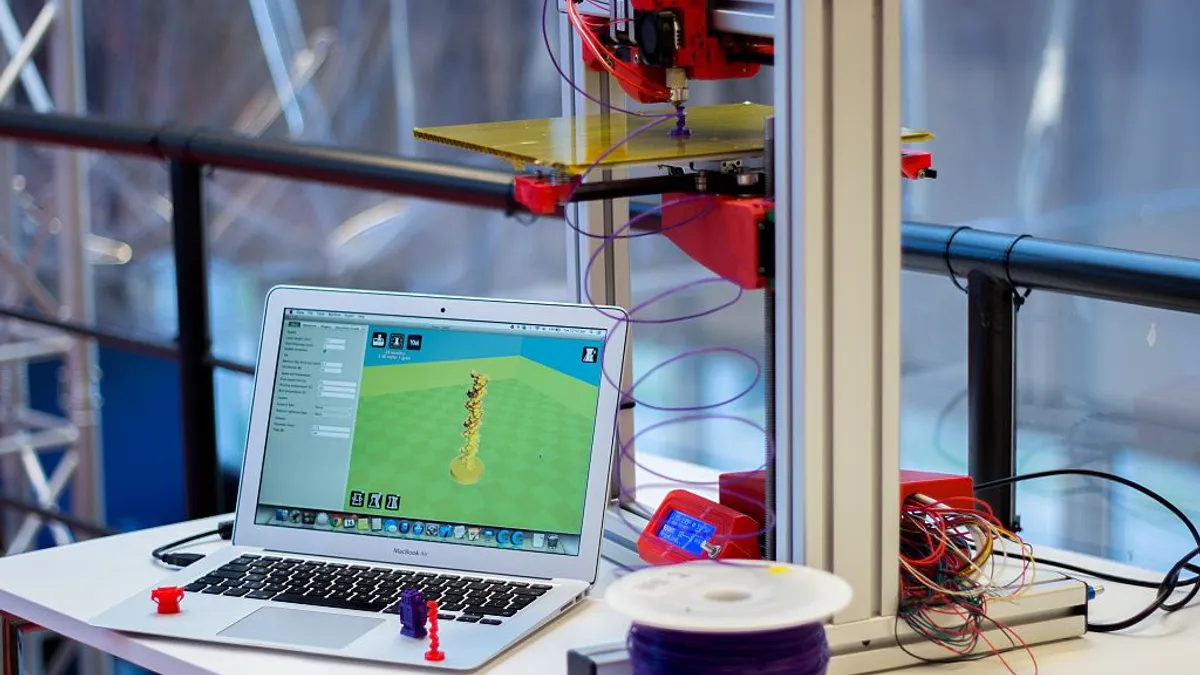

UPS and Fast Radius teamed up in 2016 to link the two companies' resources. UPS had 3D printing capabilities in more than 60 locations, and Fast Radius had software and a 3D printing factory in Louisville, Kentucky. Fast Radius's software can aid in the design, development and manufacturing of industrial-grade parts.

3D printing promises faster design and speed to market with the ability to easily make changes to the manufacturing process. And localized production can simplify supply chains and lead to less reliance on suppliers.

"By building this disruptive technology into our supply chain models, we also bring new value to our manufacturing customers of all sizes," Stan Deans, the president of UPS Global Distribution and Logistics, said in 2016 of the then-new partnership. "Additive manufacturing technology is still developing rapidly so ‘manufacturing as a service’ is a smart approach for many companies."

The two companies are trying to get ahead of the additive manufacturing evolution, which McKinsey said, "can completely change the way products are designed and built, as well as distributed, sold, and serviced."While this technology comes with benefits, there are also some limitations, according to McKinsey, including lack of design knowledge, risk of pirating and the risk of supply chain disruption.

By partnering with Fast Radius, UPS is not only placing a bet on 3D printing, it is also making a move to be a part of this supply chain disruption and not a victim of it.