Dive Brief:

- A Brooklyn start-up named Voodoo Manufacturing is capable of creating any image or design via 3-D printing, CNBC reported last week. The company is almost wholly staffed by robots.

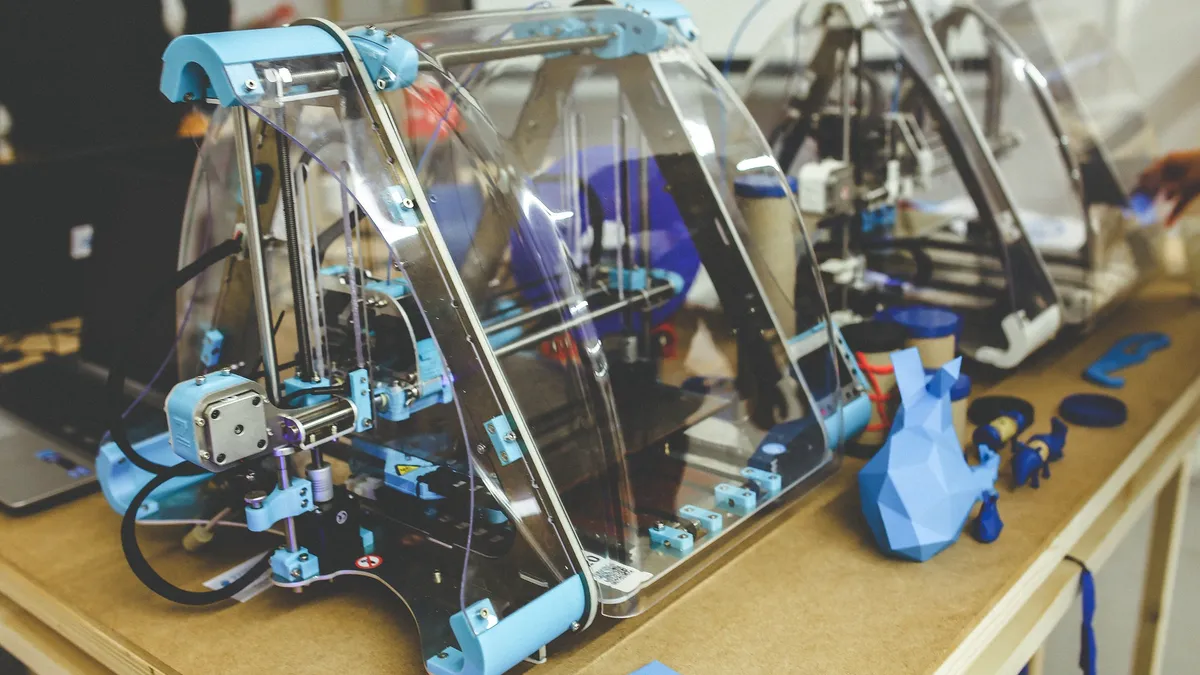

- The Voodoo factory relies on 160 3-D printers, with robots assembled from sensors, arms, grippers and other components, running the process of changing the printing plates then restarting the printers.

- Voodoo recently received $5 million in new venture investment from General Catalyst, the Y Combinator Continuity Fund and other investors, bringing its investment total to $6.4 million to date.

Dive Insight:

Not only is Voodoo Manufacturing a prototype for disruption of small parts manufacturing, but it's also an early adopter of robotic task management, fulfilling recent predictions that Voodoo and its ilk are poised to overtake the production industry.

Thanks to their ability to produce small and limited-batch pieces, 3-D printing studios could easily provide fulfillment for orders where parts manufacturers were either unavailable or too expensive. In one situation involving Volkswagen last August, the intervention of a 3-D printer could have resolved a dispute caused by shipping interruptions that caused a problematic delay. Had VW been able to access a 3-D printer, it could have quickly printed the cast iron parts it needed when its suppliers stopped deliveries.

Yet the combination of a robot-run 3-D printing facility could be alarming to some. The fact that Voodoo is considered a small business, with only 160 printers at its disposal, means that the work of the robot is unlikely to have displaced more than one or two employees performing the rote tasks of setting plates and restarting the printers. Even Voodoo acknowledges the job is unchallenging. One Voodoo investor believes the future of manufacturing jobs involves programming or machine maintenance.