Correction: In a previous version of this article, Gary Oldham, Vitech's Vice President of Sales, was misidentified. We regret the error.

The U.S. warehouse market is heating up, and with it the demand for new technologies is soaring.

In 2017, 197 million square feet of warehouse space opened up for supply chain managers to improve their speed to market. The logistics boom reflects a market to direct-to-consumer sales, with retailers and manufacturers alike placing a premium on urban hubs to decrease lead times.

"The way you move inventory to the end user is changing," said Mark Wheeler, Director of Supply Chain Solutions at Zebra Technologies, a longstanding provider of mobile warehouse technology. "That requires new workflows and new facilities and new strategies."

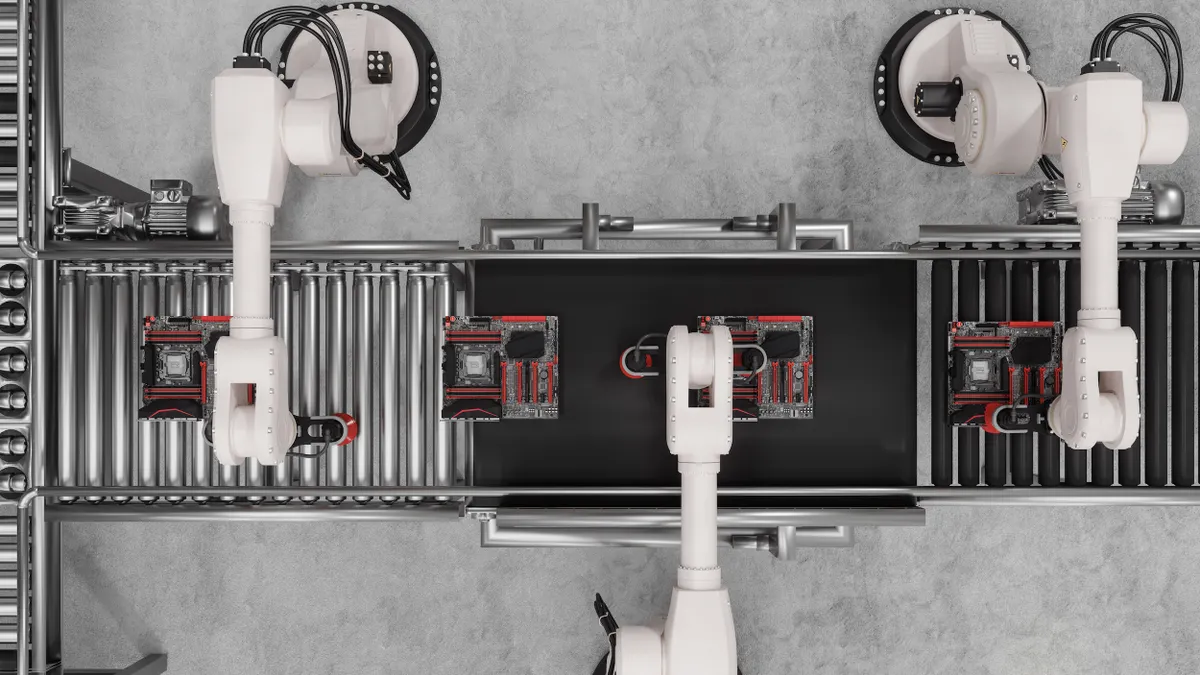

The warehouse of the future is not one that prioritizes the storage of goods, according to a white paper from Arizona State University. They are distribution or fulfillment centers, focused on the rapid movement of product in as few touches as possible.

To build this, supply chain managers are integrating new technologies – which promise increased productivity and seamless workflows – into their warehouse operations.

New technologies are being tailored to warehouse workflows

Mobile warehouse devices have been available for decades, but as the technologies that underlie them mature, operations managers are finding more, tailored options to suit their needs.

To this day, technology options generally ascribe to three main categories: the general purpose hand-held, the wearable, and the finger-managed scanners.

The user interface was predominantly terminal-based, and these terminals operated on a somewhat common language to be able to interface with warehouse management systems. But the rise of the internet of things and popularization of smartphone and voice technology among consumers has created a bit of a paradigm shift for the industry.

For a few years now, technology systems have begun transitioning to Android-based software rather than the Windows-based norm, according to Wheeler. The shift is due to the emergence of more purpose-driven devices and full-touch systems.

"Android, because of its open architecture, is really the only one that is suitable for purpose-built devices," he said. "As we go to Android, we have the ability to implement full-touch user interfaces, which are easier to learn and easier to use."

In fact, the warehouse technology industry is, in a way, chasing talent.

"In general, we see a desire for more touch user interfaces," Wheeler said.

New employees expect those systems, and employers are adjusting their expectations to match that. In five years, he said, app-users and browser-based clients may also be numerous in the warehouse.

One example of the rise of these tailor-made solutions is the emergence of voice-enabled technology.

St. Paul, Minn.-based Patterson Logistics Services, a distributor of health and animal supplies which fulfills 92% of its orders to clinics on a same- or next-day basis, recently made the transition to voice-enabled operations in 2017, according to a case study sent to Supply Chain Dive.

The distributor would handle 25,000 orders a day with paper and manual processes. To improve, the company chose to adopt an SAP solution and integrate it with Honeywell’s Vocollect voice-technology, a wearable headset provided by Vitech Business Group, a HighJump division. The result was a 25% faster filling rate, reduced training time and improved order accuracy.

Patterson Logistics Services' story shows technology alone can help drive major improvements, but only if it exists within an integrated system and workflow, a limitation which may challenge smaller businesses looking to compete.

"If you have a very complex WMS, you might look at some sort of bolt-on solution that will provide you some key functionality in a critical area," Wheeler said.

Not all new technology is suitable to your needs

"I would not say that voice is the right technology for every situation," said Gary Oldham, Vice President of Sales at ViTech. "There are some workflows that don’t lend themselves perfectly to a voice-directed workflow."

There’s a bit of a sweet spot for determining what type of technology to implement within the warehouse, and it all depends on the workflow. Voice technology, for example, works best with a pick rate that is fast enough to justify integrating time-savings from voice processes, but not too fast where voice can slow the process down, according to Wheeler.

"Today, some of the highest growth rates (in voice) aren’t even in picking," Wheeler added. Processes like inspection of fleet trucks, maintenance and discreet manufacturing are gaining steam with the technology.

Fortunately, now, the use cases for technologies like voice and augmented reality are becoming clearer, thanks to the next generation of talent that is entering the workforce and consumer use cases that are taking off.

"The knowledge of what voice recognition can do concept wise opens the door to creative thought for many people," Oldham said. "No longer do we need to spend time educating them on what voice recognition is."

And as both vendors and clients tap that creativity to create new use cases, the various existing technologies will blend together to help move inventory as fast as consumers demand. After all, both Oldham and Wheeler said voice-, augmented reality and touch technology are not fully in competition. In fact, they often complement each other on the road to building a smart facility.

"What we’re selling is not technology," Oldham said. "We’re selling productivity, technology and workflow improvement."