With new advances in robotics and artificial intelligence, virtually every player in the supply chain is looking to some form of automation.

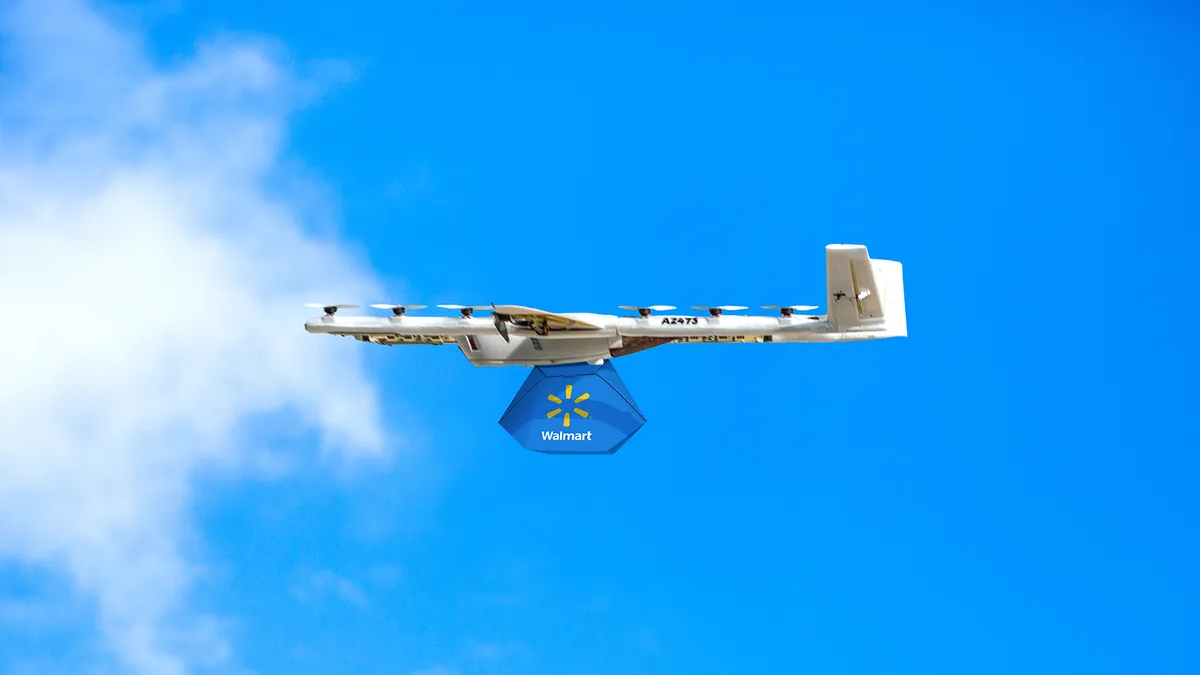

Walmart is testing grocery-picking robots. Ryder partnered with Fetch Robotics to install drones, sensors and wearable technology in its warehouses. And in its latest earnings call, DHL said it was "seeing about 25% productivity improvement" from robotics.

Automation, the companies bet, can increase efficiency, reduce costs and improve performance. But in conversations with Supply Chain Dive, experts said automated technology is not a panacea for every application or facility. In fact, there are many components of the supply chain that either cannot or should not be automated.

"Just because you can automate something doesn’t mean you should," John Santagate, research director for the service robotics market at IDC, told Supply Chain Dive. "There are aspects of supply chain that shouldn’t be automated. You can leverage technology to support things, but there are still humans required in decision making and in some processes."

Robots have limitations, too

Improving capabilities and falling costs are making small collaborative robots a growing part of the supply chain.

The trend is especially notable in warehouses. In a 2017 report, market intelligence firm Tractica estimated the number of robots operating in warehouses would grow nearly fifteen times over the following 4 years, reaching 620,000 in 2021. Over time, the firm predicted robotics processes would become "faster, safer and more productive."

Yet most robots remain limited to "menial tasks," Santagate said. Some machines can now autonomously navigate an aisle or warehouse, picking items as they go, but they lack dexterity and flexibility. Few mainstream robots can also climb stairs, travel on unfinished surfaces or make real-time movement decisions like humans.

"Many facilities aren’t suited for robots in every application. There are certain aspects of mobility and dexterity where you still need humans," Santagate said.

"Just because you can automate something doesn’t mean you should."

John Santagate

Research Director for the Service Robotics Market, IDC

There are also times when machines in the warehouse can’t understand exceptions, Brandon White, head of quality and regulatory affairs for Kenco Management Services, told Supply Chain Dive.

For example, while a machine performing shipment audits may be able to obtain a high level of accuracy in picking and packing, it can’t make outlying judgments when customers need to adjust their priorities or make last minute changes. Machines also can’t put a personal touch on a service or understand how they might be able to add value to a transaction. "You still need managers in roles where they can make those decisions and kind of judgments that a robot or AI might not be able to make," White said.

Many facilities may find that automation still isn’t cost effective for their operations or configuration, Santagate said. While small robots are now relatively affordable for straight line movement and carrying payloads, anything that requires a robotic arm could triple the cost and compound the complexity.

"Today you still have people in the aisles taking items off of shelves and dropping them in bins, because it’s more cost-effective to do so, and the people are able to do it more quickly," Santagate said.

Humans are the best managers and forecasters

Even the most automated facilities still need human oversight, Santagate said.

When JD.com opened a fully-automated fulfillment warehouse in Kunshan, China in June 2018, it still needed four human workers to service the robots. While automated machinery pulls products from trucks and moves them around the facility with conveyors and driverless forklifts, humans ultimately control the machines.

Humans are also more powerful and accurate when it comes to planning, forecasting and judgment, Santagate said. He has designed sales and operations planning (S&OP) and demand-planning processes for large organizations and said while software can enable forecasts, they’re not always accurate because they’re incapable of considering the human element. Automation should only be used as a foundation, not an exclusive decision maker.

"There are certain aspects that statistical models don’t consider. The salesman knows he just had a conversation with company XYZ and they said they’re going to place a very big order," Santagate said.

Relationships and soft skills remain workers’ competitive edge

Sales forecasting, human resource management and administration are some of the areas of the supply chain that are unlikely to ever be fully automated, for a key reason: they require human relationships.

"There’s a lot of talk about artificial intelligence but at the end of the day, it’s still programming. It’s programmed intelligence," Santagate said. Artificial intelligence has advanced to where some applications can now make judgments, but computers still cannot think "beyond their programming."

There are also many situations that require human perception and awareness that machines cannot replicate, White said. For example, while AI can automate human resources (HR) procedures such as on-boarding or orientation, it can’t have empathy to understand illnesses or matters related to the Family and Medical Leave Act (FMLA). Kenco maintains HR personnel at all its facilities and said it’s not something he could see going away.

"You’re always going to need someone who can read a situation and understand social cues, an HR person or a general manager who can ‘read’ employees if something’s going on in their personal life or work performance," White said.

This story was first published in our weekly newsletter, Supply Chain Dive: Operations. Sign up here.