Sharp growth in eCommerce since the pandemic has heightened the need to increase logistics productivity and efficiency. Meanwhile, pressure from customers, suppliers, investors and others is prompting many logistics businesses to seek more environmentally sustainable ways to operate.

These trends may not be impacting all logistics companies at the same time. But they are shaping the industry. Either trend may be a focus for your business now, and both will likely be a focus sooner or later.

Can linerless labels help?

There’s no single way to respond to these trends. However, many solutions do exist to help logistics businesses align their operations with the needs of the 21st-century market. Some of these solutions may be less obvious than others, but they nevertheless may offer significant and measurable benefits.

Linerless label materials are one such solution

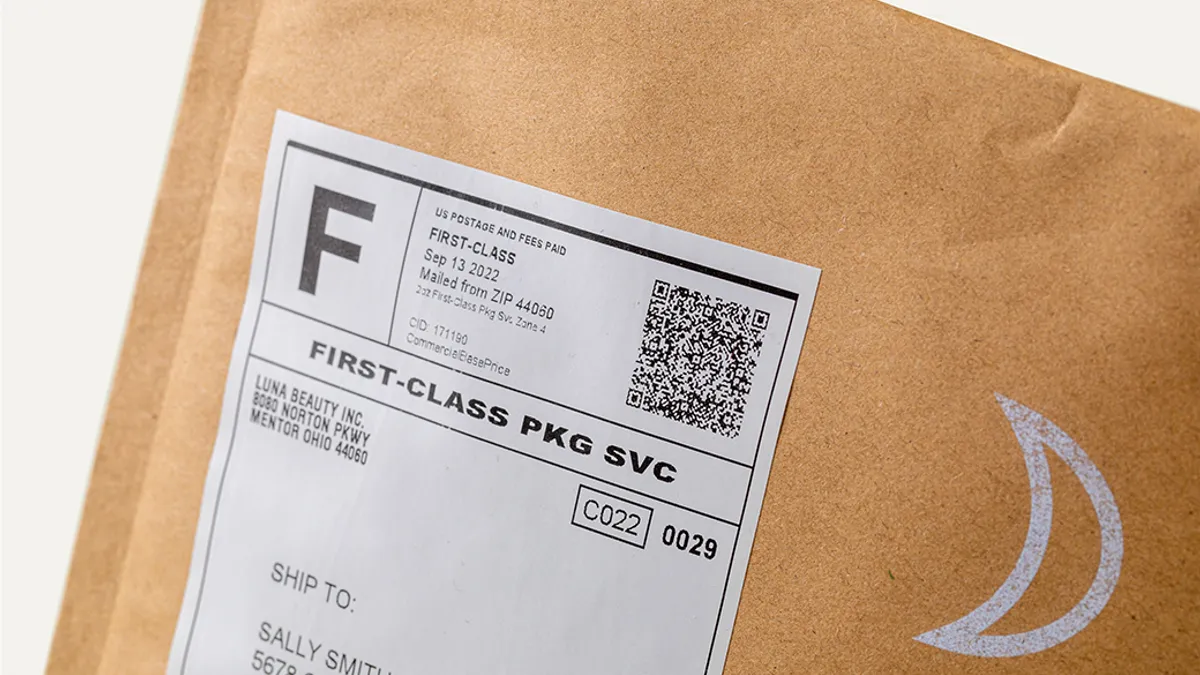

We’re referring to the materials used for address and other variable-information labels printed with direct thermal technology. They’re then adhered to packages—either manually or automatically—with pressure-sensitive adhesives.

With all you have to think about, those variable information labels might not be very high on your list of priorities. But maybe they should be.

Dissecting a linerless label

A traditional label construction typically has three layers: a facestock (heat-sensitive paper for direct thermal printing applications), a pressure-sensitive adhesive and a siliconized liner that prevents each layer of labels from adhering to each other in a roll. The facestock is usually die-cut to delineate the usable label from any excess material, known as matrix. During application, the liner and matrix are removed and discarded.

A linerless construction, as the name implies, does not include the liner or matrix. Instead, a release coating is applied to the facestock during the construction’s manufacture. This coating allows labels to be unrolled easily and cleanly.

Linerless label technology uses 33% less material and allows 50% more labels to be included in a roll of standard volume and weight. It also removes virtually 100% of post-application waste.

With linerless labels, less is truly more. Depending on the size and volume of the business, switching to linerless can have a significant positive impact on a logistics operation’s productivity and carbon footprint.

Linerless labels in logistics: The benefits

The logistics industry uses a wide variety of label-making and application technologies and approaches. These range from highly manual and “low speed” processes to highly automated lines that can place labels on dozens of packages per minute.

But whatever approach is used by your business, you may be able to benefit from linerless.

Improved productivity

Linerless labels come off the printer ready to apply. In manual applications, an employee doesn’t have to fuss with peeling and discarding a liner and matrix. Using linerless labels means employees can stay on task rather than stopping to sweep and dispose of that waste (which, if not removed, could pose a slip-and-fall hazard).

Linerless technology also packs more labels per roll. So whereas a six-inch traditional roll might have 1,000 label blanks, a six-inch linerless roll could include enough material for 1,500 labels. This decreases the frequency of label roll changeovers, increasing uptime.

Improved sustainability

As noted above, linerless labels are manufactured with dramatically less raw material than traditional labels and they produce no landfill waste on the back end. Both of these can have a positive impact on your business’s scope 3 emissions and overall sustainability goals.

Linerless label technology reliability and performance

Linerless technology has come a long way since its introduction a decade ago. The materials are more reliable and even easier to use than ever.

As a leading provider of linerless label materials, Avery Dennison offers a portfolio of constructions that are compatible with a wide range of application equipment, from handheld printers to room-sized, automated application lines. These constructions offer robust image and background stability for barcode scanning and readability.

Its adhesives are engineered for a variety of substrates, including paper-based cardboard and high-post-consumer-waste-content materials that are commonly used in eCommerce today. They offer application and durability performance across a wide range of environmental conditions, including temperature extremes, moisture and UV light. And when combined with Avery Dennison’s release coating, these adhesives reduce ooze which leads to the “gumming up” of equipment that sometimes happens with other products. This lowers maintenance needs and equipment downtime, further enhancing productivity.

Explore how linerless labels can help your logistics business

So what’s next? As we said at the outset, trends such as the growth of eCommerce and the pressure to be more sustainable may not be affecting your business right now. But these are trends with staying power. Sooner or later, you’ll need to address both with solutions that produce results.

Now is the time to explore how linerless labels can help your logistics business. Your labeling equipment provider is the place to start. They should be able to help you better understand your equipment options and potential return on investment. And when it comes time to spec out linerless label materials, you can count on Avery Dennison. We welcome the opportunity to discuss your needs and share the many options in our portfolio. Learn more at label.averydennison.com/linerless.