Dealing with returns as a part of reverse logistics can be a struggle for ecommerce order fulfillment – especially in the retail and consumer goods industries. Returns are an inevitable part of ecommerce and facing this issue head-on can improve customer experience, decrease damages and reduce costs.

Ecommerce Dependence on Returns

The total amount of goods purchased online is increasing every year and with it – the amount of returns. One estimate shows that for online clothing retailers, as much as 40% of all purchases are returned. Of those returns, it is typical to have less than half in good enough condition to be made available for full-price resale.

Even with the hit to the bottom line, a good return policy is critical for consumer growth. An industry survey reported consumers ranked free returns and exchanges as the #2 most important incentive to online shopping, behind free shipping.

How retailers handle the returns process impacts many aspects of the business:

- Customer service and public relations

- Products

- Transportation and shipping

- Warehouse labor and storage

Online Retailer Finds a Solution

To confront the issue of returns, this clothing retailer decided to tackle returns on their own terms:

- Standardize customer returns

- Provide a positive customer experience

- Improve fulfillment center efficiency

As part of the shopping experience, every order is delivered to the customer with a folded bag, pre-labeled and pre-paid making returns easy. Customers drop in their unwanted items, seal up the bag and leave it with USPS to ship back to the retailer.

Easier Return Process for Customers

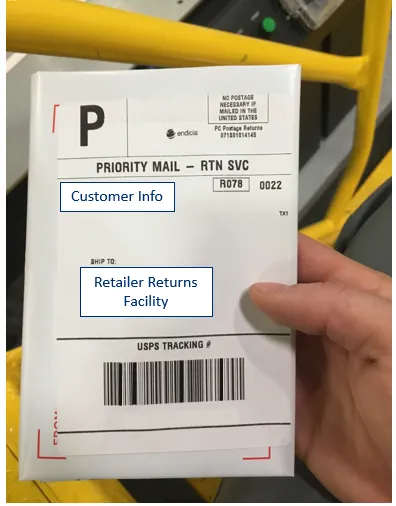

For the customer, the ease of this process is a big win because while many retailers provide paid-for shipping labels, customers are hassled by having to provide a box or bag to ship the return in. The bag is a USPS “polybag” that is folded to the size of the 4 x 6” shipping label and included with each order. A standardized process increases the efficiency of the return and label tracking allows customers to see updates to the return as it is in-process, creating peace-of-mind for when to expect a refund or credit.

Streamlined Return Processing for Retailer

For the retailer, the label has a unique shipping and returns address for the order, which matches the return with the original customer order. When the polybag is received back at the distribution center it can easily be scanned, the customer is refunded, and the contents are repurposed.

Just as some retailers mandate standards to their vendors for new inbound product (re: routing guide), this polybag sets a standard for customer returns, making sortation and product handling at the distribution center more streamlined.

The Bastian Solutions team collaborated with the retailer to develop an automated solution to include the returns polybag with each order. Here is that process:

- Each carton is automatically scanned to determine the correct polybag size and to print the unique returns label.

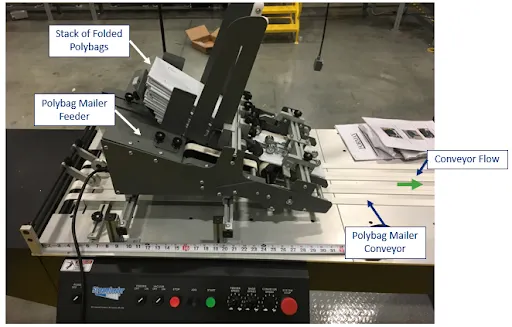

- The polybag is dispensed from a feeder toward an automatic label applicator, see figure 1.

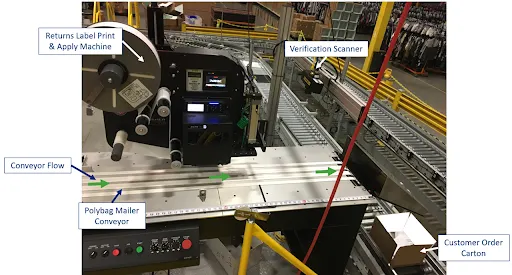

- The label is applied and scanned for verification to be sure it matches the customer's order, see figure 2.

- If the scan passes, the polybag is ready to go to the customer. It drops into the order carton as the finishing touch before the order is sealed and shipped out the door!

As customers expect more from online shopping, making returns easy is something ecommerce fulfillment companies need to think about. This is one retailer’s solution to create a smooth experience for their customers while save time and money along the way!