Stat of the Week: Page 4

Each week, Supply Chain Dive takes a look at a report, survey or indicator for a glimpse of present and future trends. Look out for these articles in your inbox by subscribing to Supply Chain Dive: Operations.

-

Warehouse capacity contracts as imports arrive amid low demand, closed storefronts

XPO and Flexe said customers are looking for places to store inventory that has nowhere else to go.

By Matt Leonard • May 12, 2020 -

"IKEA Anderlecht self-serve warehouse" by Trougnouf is licensed under CC BY-SA 4.0

"IKEA Anderlecht self-serve warehouse" by Trougnouf is licensed under CC BY-SA 4.0

Quarterly inventories fall for first time since 2018

Depleted inventories in the first quarter were largely the result of supply issues, but this will transition to a demand-driven reduction moving forward, experts suggest.

By Matt Leonard • May 4, 2020 -

Pandemic could cost Tractor Supply an extra $50M in operations spend

Most of the expected expenses, about 80%, are related to labor or benefits, while the remaining 20% is for supplies, safety and cleaning, executives said.

By Matt Leonard • April 28, 2020 -

How a new framework can improve an existing inventory management system

For one hospital pharmacy, researchers found inventory management is about using the tools available and looking beyond cost.

By Matt Leonard • April 20, 2020 -

The image by Zulu84 is licensed under CC BY-SA 4.0

The image by Zulu84 is licensed under CC BY-SA 4.0

Warehouse storage should consider SKU correlation and picker traffic, study finds

A group of researchers from Binghamton University concluded in a paper published earlier this year that warehouse operators should consider picking delays caused by warehouse traffic when building fulfillment models.

By Matt Leonard • April 7, 2020 -

"IKEA Anderlecht self-serve warehouse" by Trougnouf is licensed under CC BY-SA 4.0

"IKEA Anderlecht self-serve warehouse" by Trougnouf is licensed under CC BY-SA 4.0

Inventory, network optimization among most widely adopted supply chain technologies

More than half of survey respondents said they think inventory management technology has the potential to disrupt the industry or provide a competitive advantage to users.

By Matt Leonard • March 31, 2020 -

So only 12% of supply chain pros are using AI? Apparently.

Low-level AI implementation could be the result of the difficulty hiring technology talent and the inability to properly manage enterprise data streams, according to experts.

By Matt Leonard • March 24, 2020 -

53% of US manufacturers expect operational impact from coronavirus: survey

Operational changes include the implementation of business continuity plans involving workplace sanitation, limiting in-person interaction and managing shifts to account for an uptick in worker absences, according to The National Association of Manufacturers.

By Matt Leonard • March 17, 2020 -

What tech and metrics do you need for omnichannel?

A modern order management system will have most of the data needed to measure omnichannel success. However, some operations will require more creativity.

By Matt Leonard • March 9, 2020 -

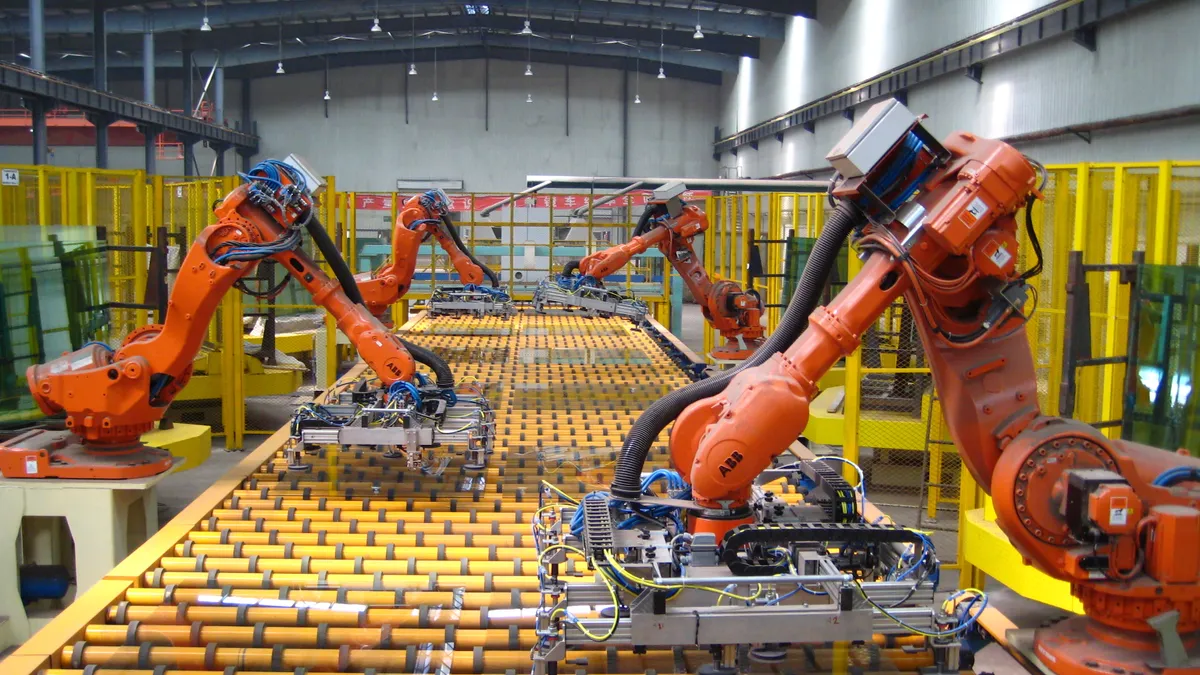

Each industrial robot displaces 1.6 workers: report

China has seen the greatest decline in its manufacturing workforce since 2000, with 550,000 fewer people working in the sector as of 2016.

By Matt Leonard • March 3, 2020 -

Internal actors account for 30% of cyberattacks in manufacturing

Proper network segmentation can minimize the threat from internal actors by limiting access to applications or databases to specific employees.

By Matt Leonard • Feb. 25, 2020 -

Flexible plastic makes up 28% of global packaging: report

PET bottles and flexible plastic are lightweight, easily customizable and cheap to manufacture, the association wrote in its "2019 Global Packaging Trends" report.

By Matt Leonard • Feb. 10, 2020 -

How manufacturers are preparing for the next recession

More than half of respondents in a BDO survey said they were working to increase production efficiency to guard against a future recession and 42% said they were monitoring the financial health of their suppliers.

By Matt Leonard • Feb. 4, 2020 -

How wearables compare: Head-mounted, wrist worn or gloves?

Managers who use wearables in their operations say it helps employees do their jobs faster and with fewer errors, but benefits can depend significantly on the hardware.

By Matt Leonard • Jan. 21, 2020 -

Spending on robotics forecast to exceed $112B in 2020: IDC

These robotic systems increase efficiency, but tariffs could add to their cost — a factor businesses consider to be a challenge.

By Matt Leonard • Jan. 13, 2020 -

Manufacturing, supply chain see greatest cost savings from AI: McKinsey

Cost reductions from the use of artificial intelligence are typically the result of better forecasting and analytics, not headcount reduction.

By Matt Leonard • Jan. 7, 2020 -

How Celect optimized Urban Outfitter's e-commerce fulfillment

The analytics company built an algorithm that doesn't just consider shipping cost, but also the risk of lost sales when fulfilling online orders from brick and mortar locations.

By Matt Leonard • Dec. 16, 2019 -

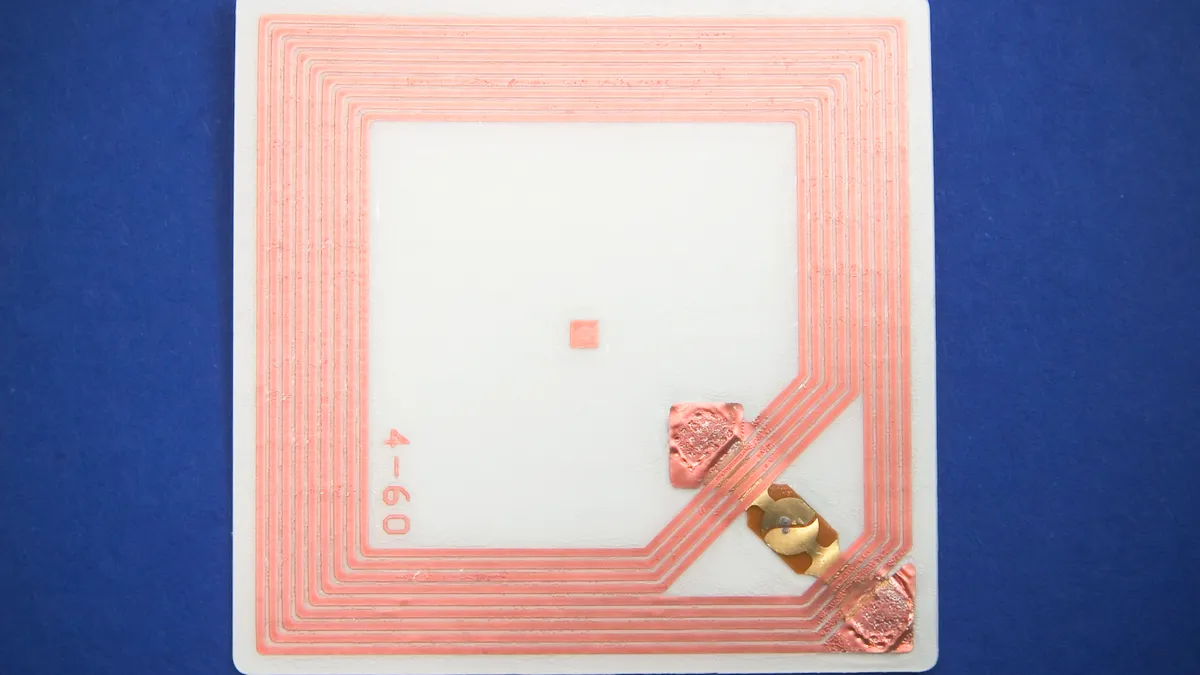

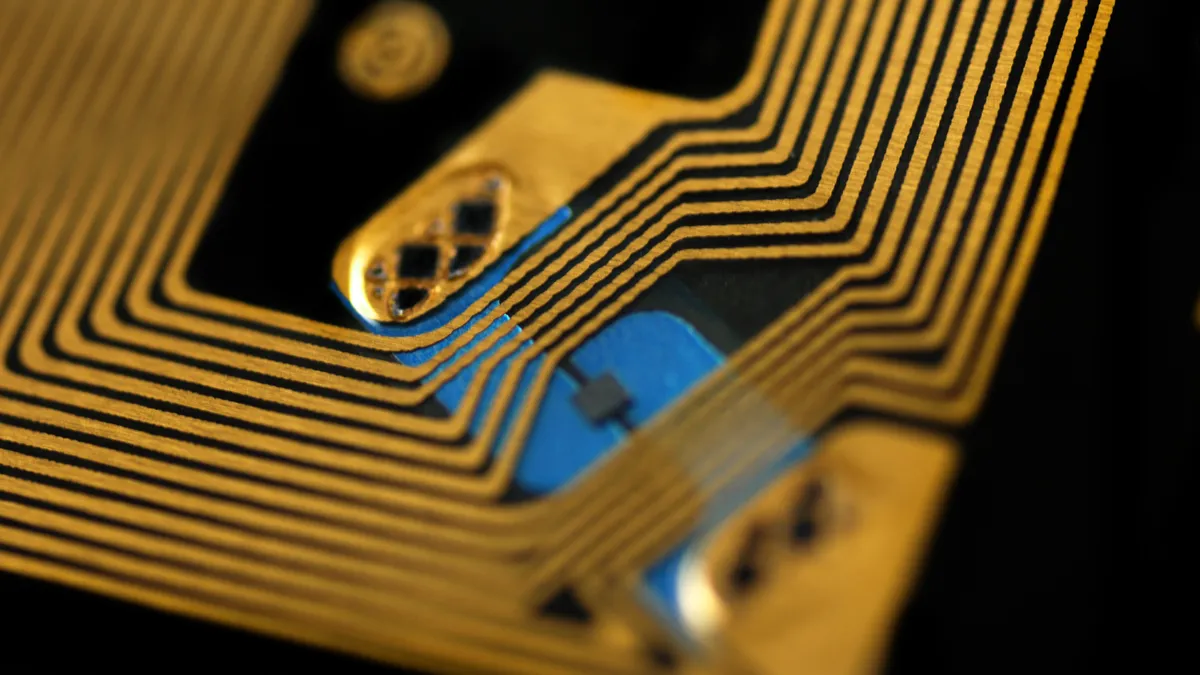

How RFID can enable omnichannel

The technology provides better visibility into a retailer's inventory, which is vital as companies expand into omnichannel offerings.

By Matt Leonard • Dec. 10, 2019 -

Study: Increased use of robotics led to worker displacement in Midwest

Nationally, the study found the use of robots can increase employment, noting there is little evidence the use of robotics will result in "widespread and crushing job displacement."

By Matt Leonard • Dec. 2, 2019 -

These 4 charts explain Amazon's fulfillment speed

Amazon's speed is key to how it plans to compete with large retailers. These charts help explain its investment.

By Matt Leonard • Nov. 25, 2019 -

Private inventories grew by $67 billion in third quarter

Some of the inventory growth can be attributed to tariffs, but some could also be explained by businesses trying to keep up with the new standard speed of e-commerce.

By Matt Leonard • Nov. 19, 2019 -

Sanofi reduces chemical, water use more than 90% with continuous manufacturing

While the pharma industry had been slow to adopt continuous manufacturing, Sanofi's new plant signals the shift is underway and those adopting the process are seeing benefits.

By Matt Leonard • Nov. 12, 2019 -

Yeti's growing DTC business and what it means for operations

Companies making the transition from wholesale to DTC can see it pay off in improved margins, but operational changes to distribution centers and purchase orders must also occur.

By Matt Leonard • Nov. 5, 2019 -

Switching from barcode to RFID can save on labor cost, product loss

When a denim manufacturer in Turkey began using RFID, it realized thousands of euros in monthly savings.

By Matt Leonard • Oct. 29, 2019 -

Warehouse or store? Picking the wrong place to unpack can cost you

Retailers can see "considerable savings" if they unpack case packs at a distribution center before shipping the product to the final store, though the model creates higher picking and facility labor costs and is incompatible with cross-docking.

By Matt Leonard • Oct. 22, 2019